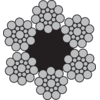

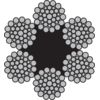

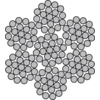

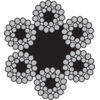

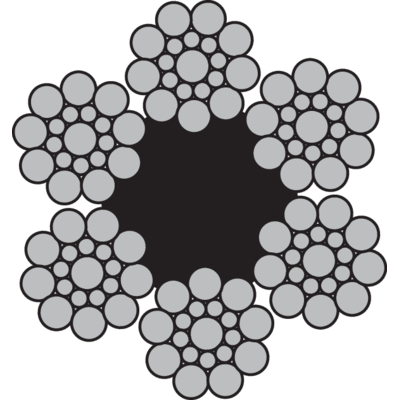

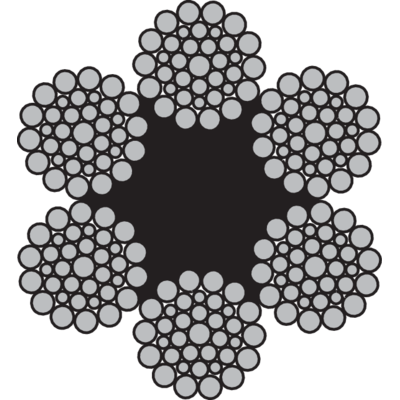

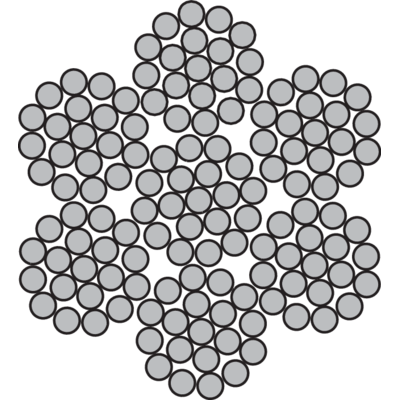

Types of wire rope sling and techical information about wire rope slings

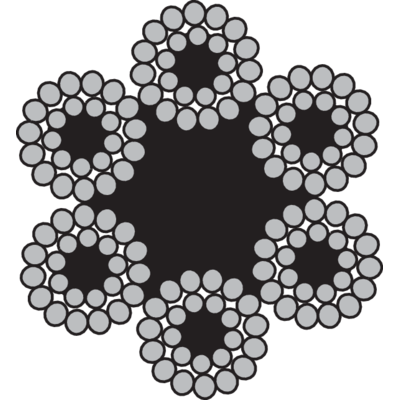

Manufacturing of steel wire rope slings

General: Steel wire rope slings are in most cases easier and less expensive than chain slings. Galvanised wire rope provides good protection against corrosion, in extreme environments stainless wire ropes can be used. For extremely heavy lifting wire rope slings are usually the best option.

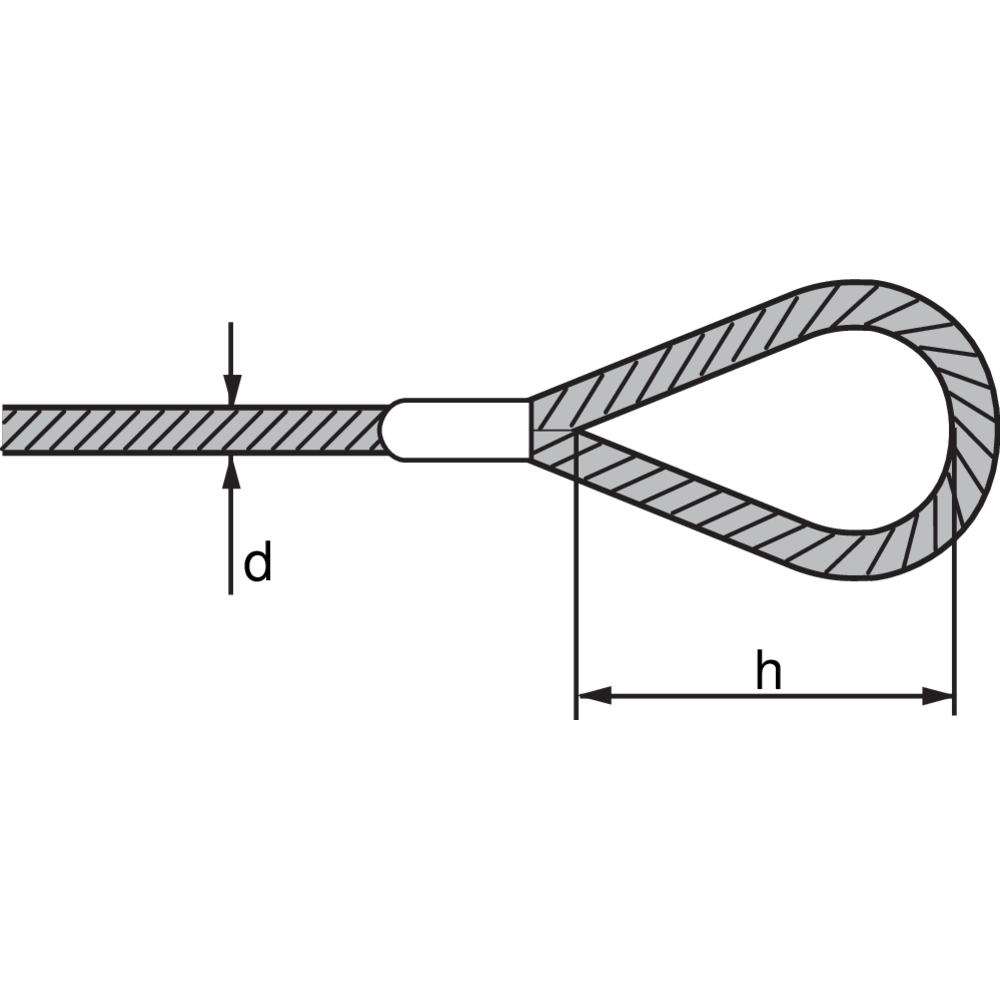

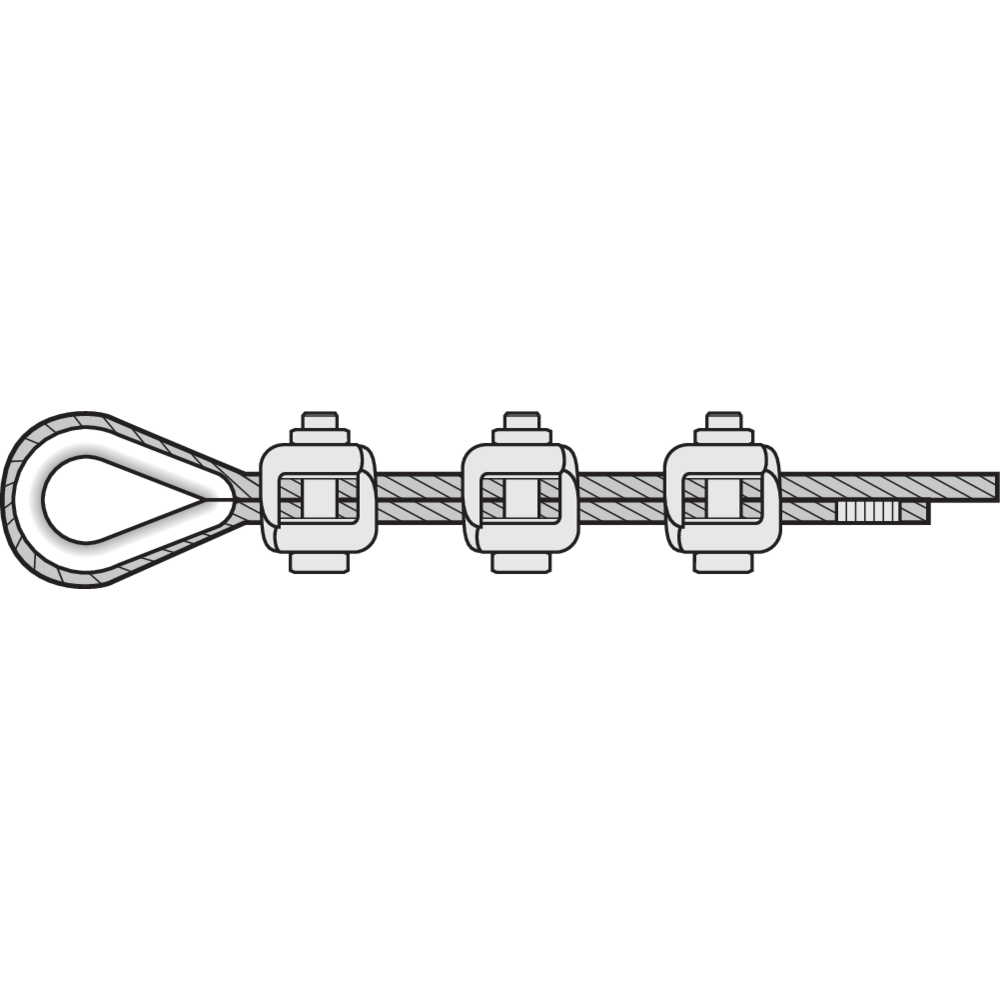

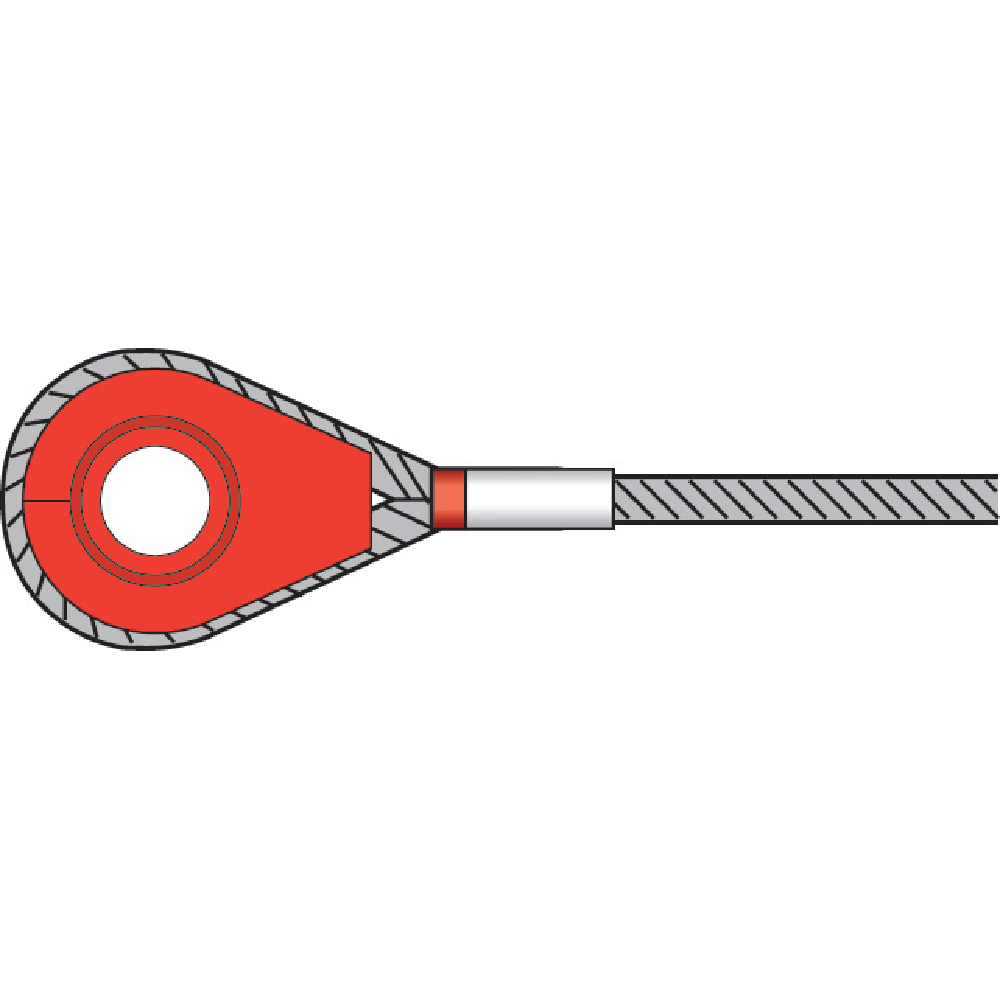

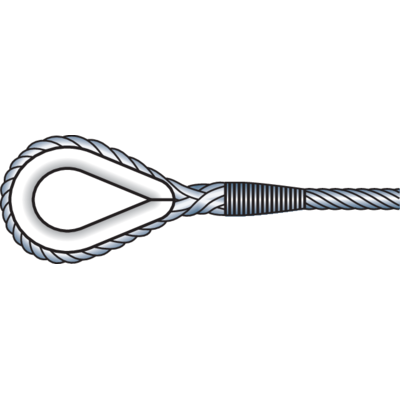

Material/Design: For manufacturing of wire rope slings the rope grade shall be either 1770 or 1960 N/mm². In multi-leg slings the rope dimension and grade shall be the same for each leg. The working load limit of the lower terminal fitting(s) shall be at least equal to that of the leg(s) to which it is/they are fitted. Where a terminal fitting is used, the eye termination shall always be fitted with a thimble. For 3- and 4-leg slings a master link with intermediate link should bee used.

Safety factor: 5:1.

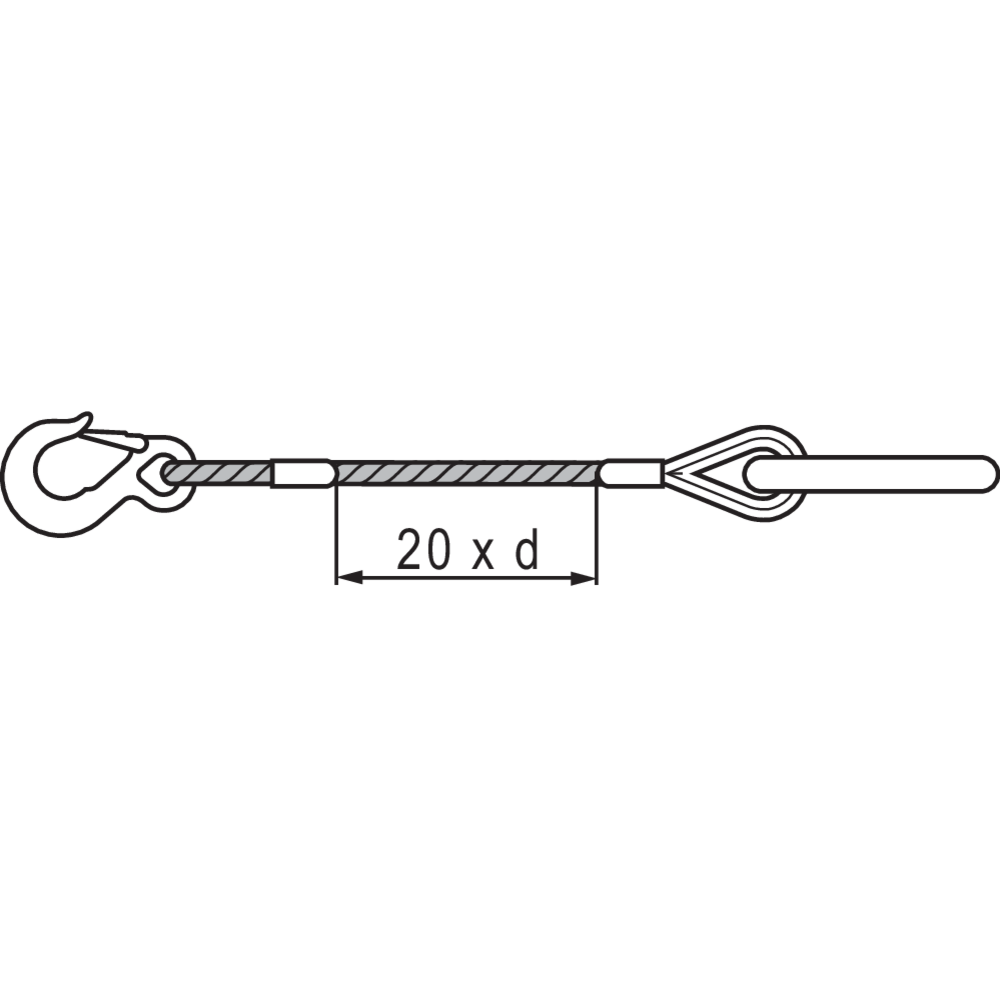

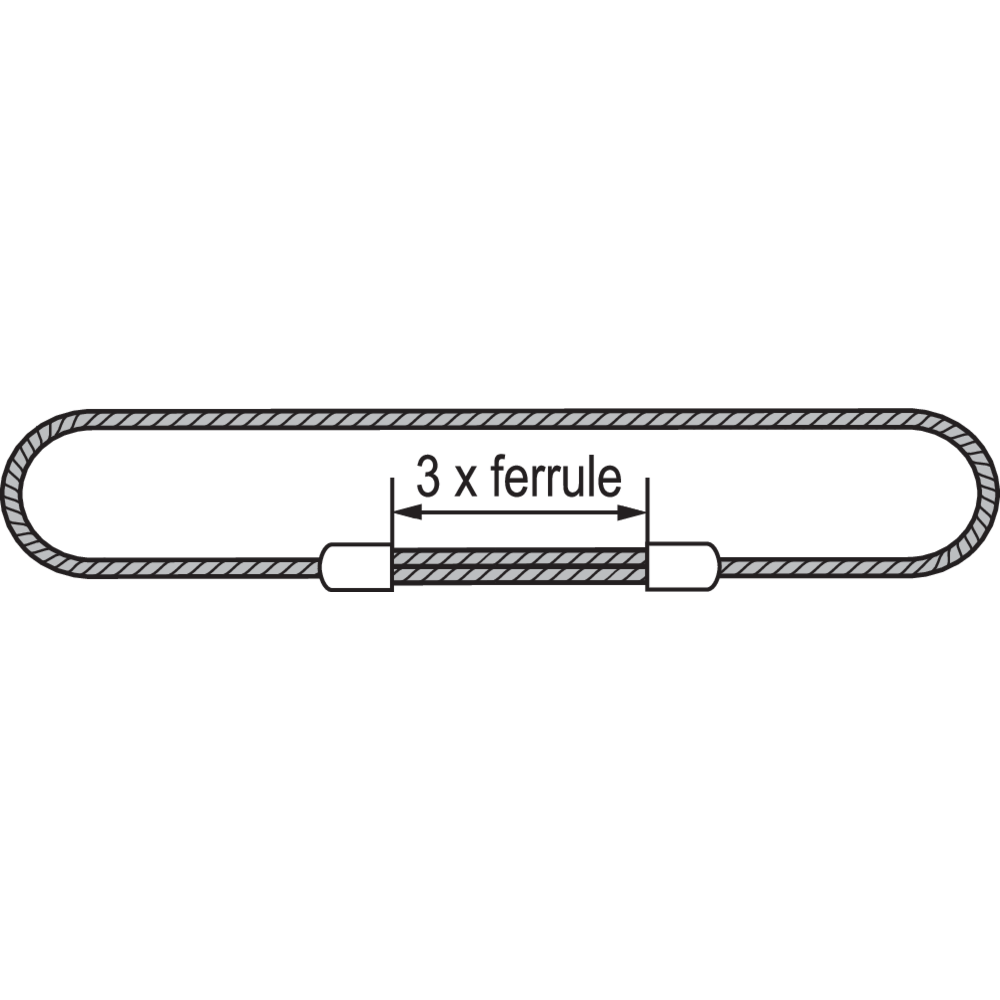

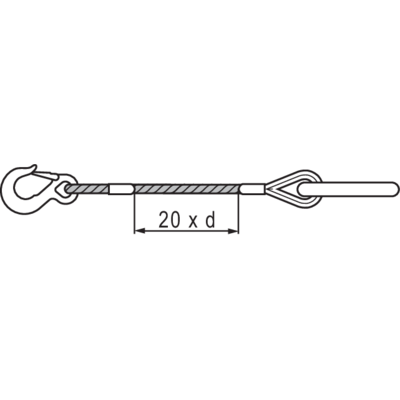

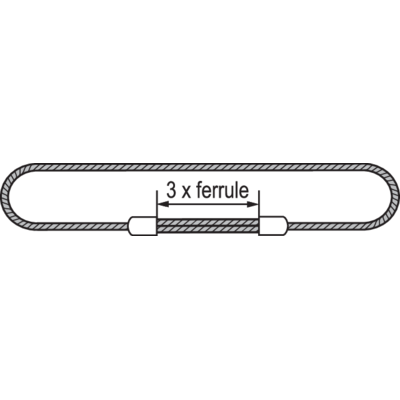

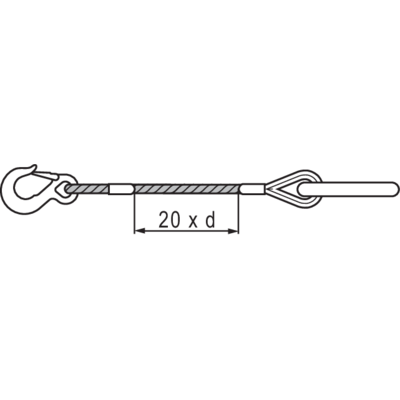

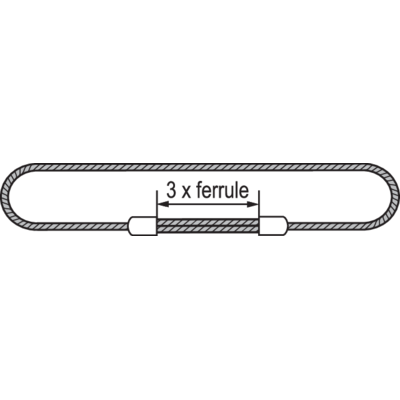

The minimum length between ferrules

The minimum length of plain rope between the inside ends of ferrules terminating a sling leg shall be 20 times the nominal rope diameter. The minimum length of plain rope between the tails of splices shall be at least 15 times the nominal rope diameter. For endless sling the length between the ferrules shall not be less than three times the length of the ferrule after pressing.

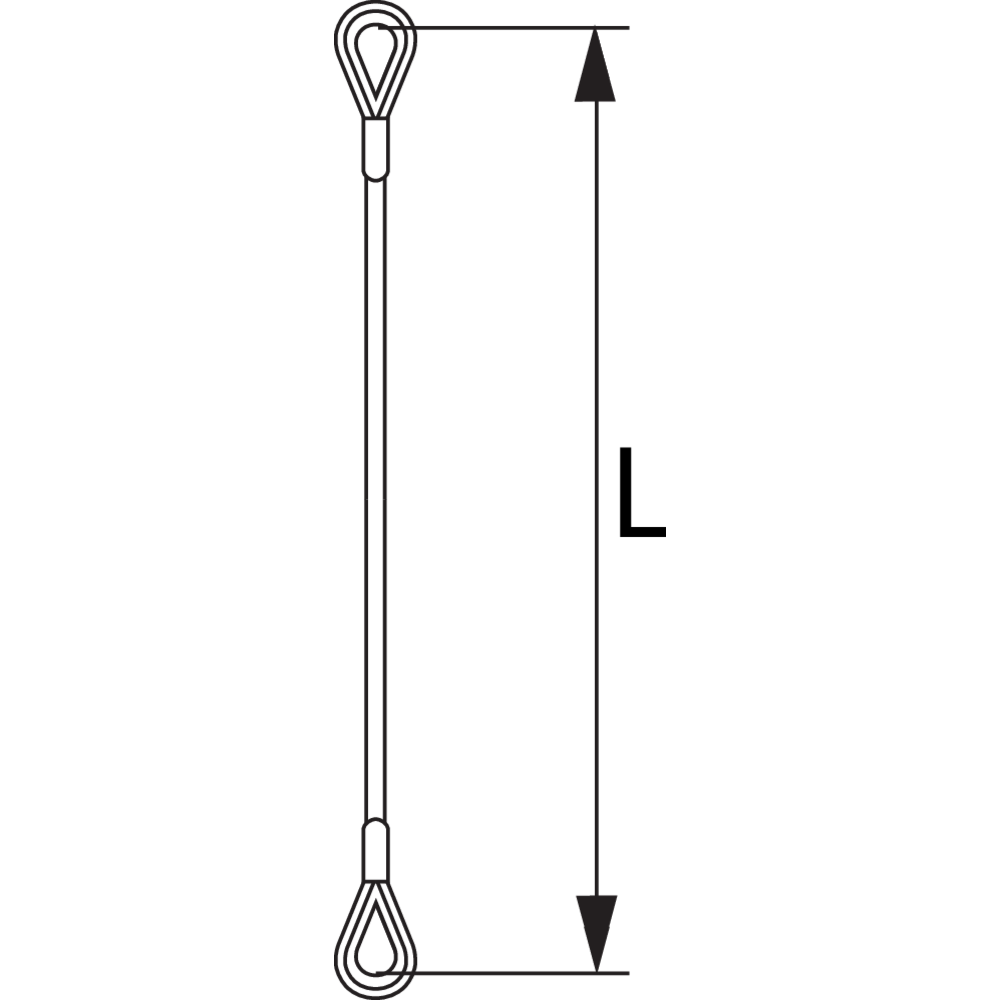

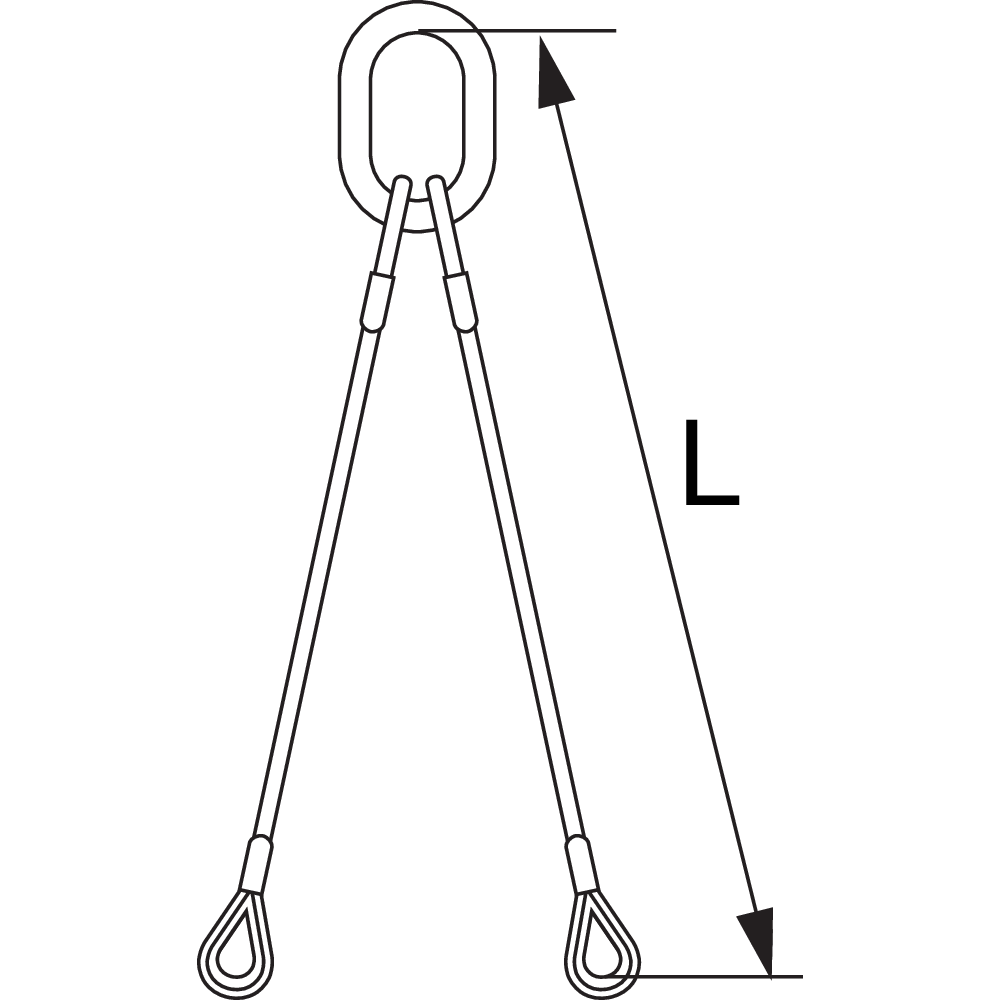

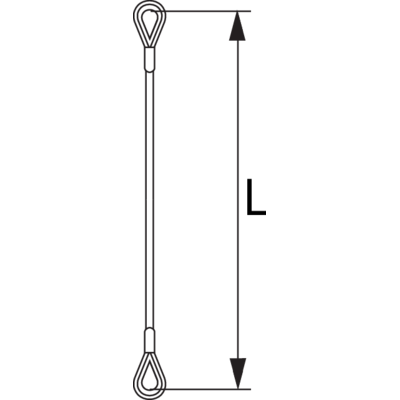

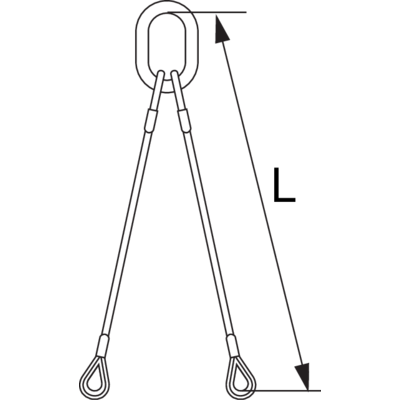

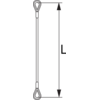

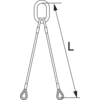

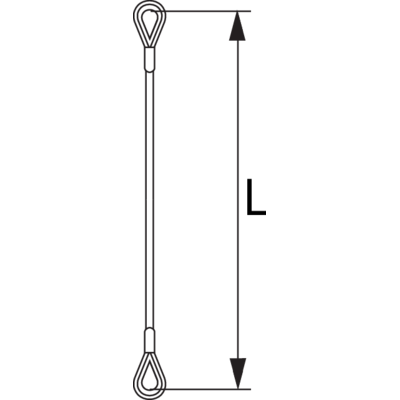

Determination of length of steel wire rope sling

Garums

Garums (L) ir attālums starp stropes slodzes pielikšanas punktiem vai cilpveida stropes apkārtmērs.

Vienzaru un riņķveida stropes

Ar čaulu nostiprinātas stropes garums nedrīkst atšķirties no nominālā garuma par vairāk nekā 2 troses diametru tiesu vai 1% no nominālā garuma, atkarībā no tā, kurš ir lielāks.

Stropes ar savijumu garums nedrīkst atšķirties no nominālā garuma par vairāk nekā 4 troses diametru tiesu vai 2% no nominālā garuma, atkarībā no tā, kurš ir lielāks.

Ja stropes ar vienu atzaru ir paredzētas izmantošanai komplektā, vienā komplektā ietilpstošo ar metāla uzgaļiem nostiprināto gredzenveida stropju garumu atšķirība nedrīkst pārsniegt troses diametra tiesu vai 0,5% no nominālā garuma, atkarībā no tā, kurš ir lielāks.

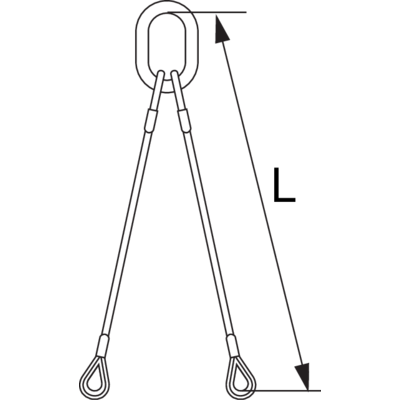

Vairākzaru stropes

Ar čaulu nostiprinātas stropes viena atzara garums nedrīkst atšķirties no nominālā stropes garuma par vairāk nekā 2 troses diametru tiesu vai 1% no nominālā garuma, atkarībā no tā, kurš ir lielāks.

Vairāku zaru stropes zaru garumu starpība bez slodzes nedrīkst būt lielāka par 1,5 troses diametru tiesu vai 0,5% no nominālā garuma, atkarībā no tā, kurš ir lielāks.

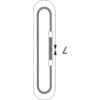

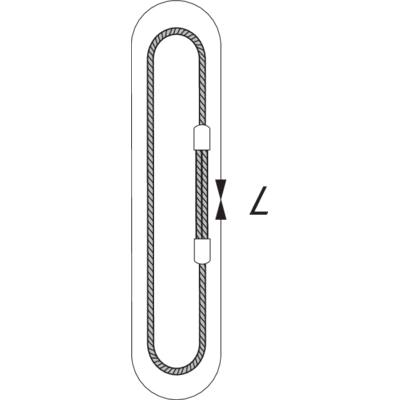

“Vītās” (kabeļu vītās) riņķveida stropes

Kabeļu vīto stropju ar diametru <61 mm garuma pielaide ir ±1d vai 1% no nominālā garuma, atkarībā no tā, kurš ir lielāks. Kabeļu vīto stropju ar diametru >65 mm garuma pielaide ir ±0,5d vai 0,5% no nominālā garuma, atkarībā no tā, kurš ir lielāks.Length

The length (L) shall be that measured between the bearing points of the sling or the circumference length of an endless sling.

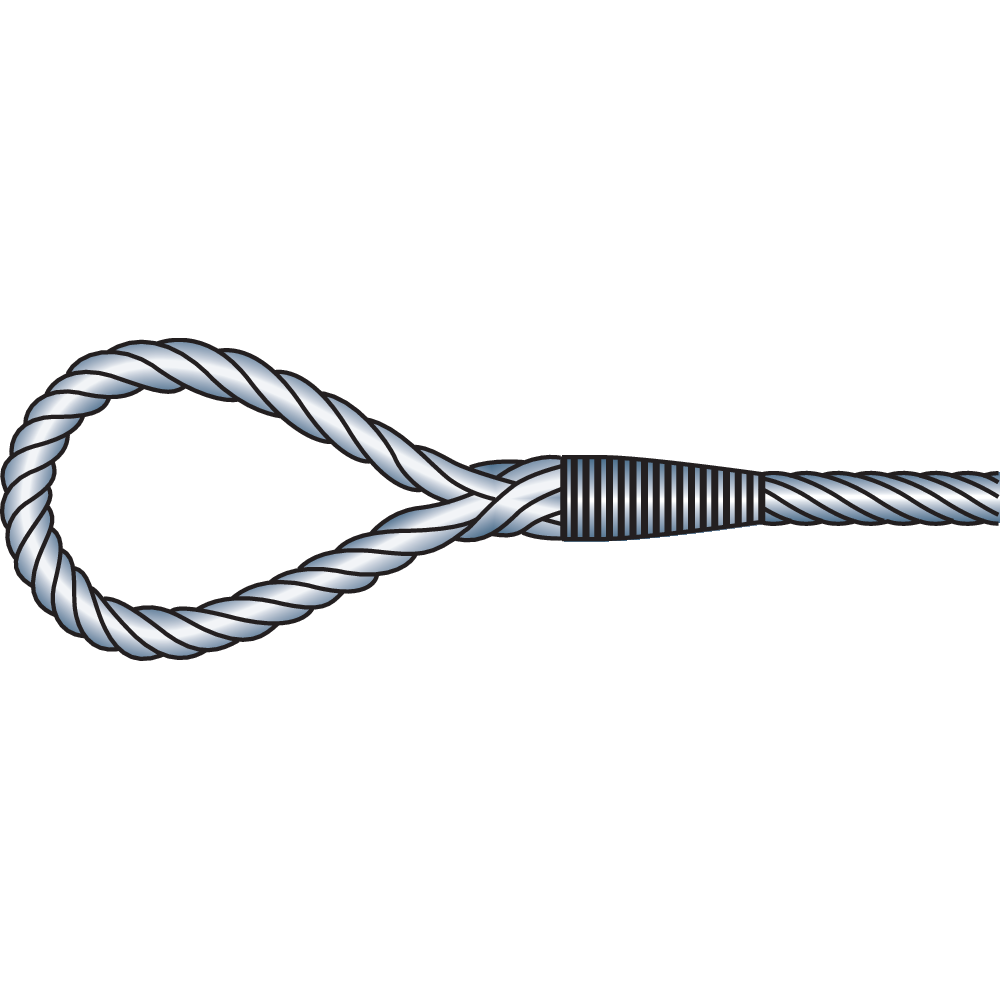

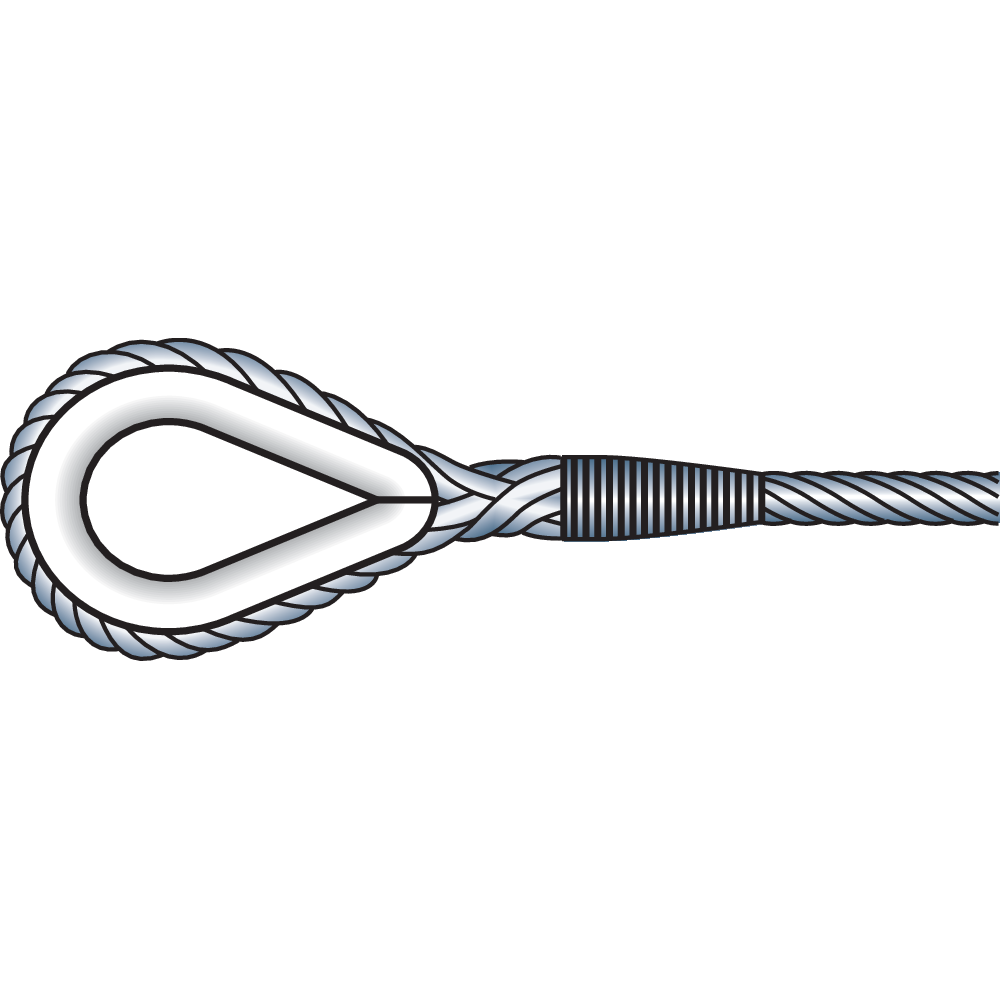

Single leg and endless slings

The measured length of a ferrule-secured sling shall not differ from the nominal length by more than two rope diameters or 1 % of the nominal length, whichever is the greater.

The measured length of a spliced sling shall not differ from the nominal length by more than four rope diameters or 2 % of the nominal length, whichever is the greater.

Where single leg slings are intended to be used as matched sets, the difference in length of matched sets of ferrule-secured eye slings shall not exceed the rope diameter, or 0,5 % of the nominal length, whichever is the greater.

Multi leg slings

The measured individual leg length of a ferrule-secured sling shall not differ from the nominal length of the sling by more than two rope diameters or 1 % of the nominal length, whichever is the greater.

The difference in length between the individual legs of any multi-leg sling under no load shall not exceed 1,5 times the rope diameter or 0,5 % of the nominal length, whichever is the greater.

"Laid" (cable-laid) endless slings

The measured length for cable-laid grommets with diameter <61 mm the tolerance shall be ±1d or 1% of the nominal length, whichever is the greater. For cable-laid grommets with diameter >65mm the tolerance shall be ±0,5d or 0,5% of the nominal length, whichever is the greater.

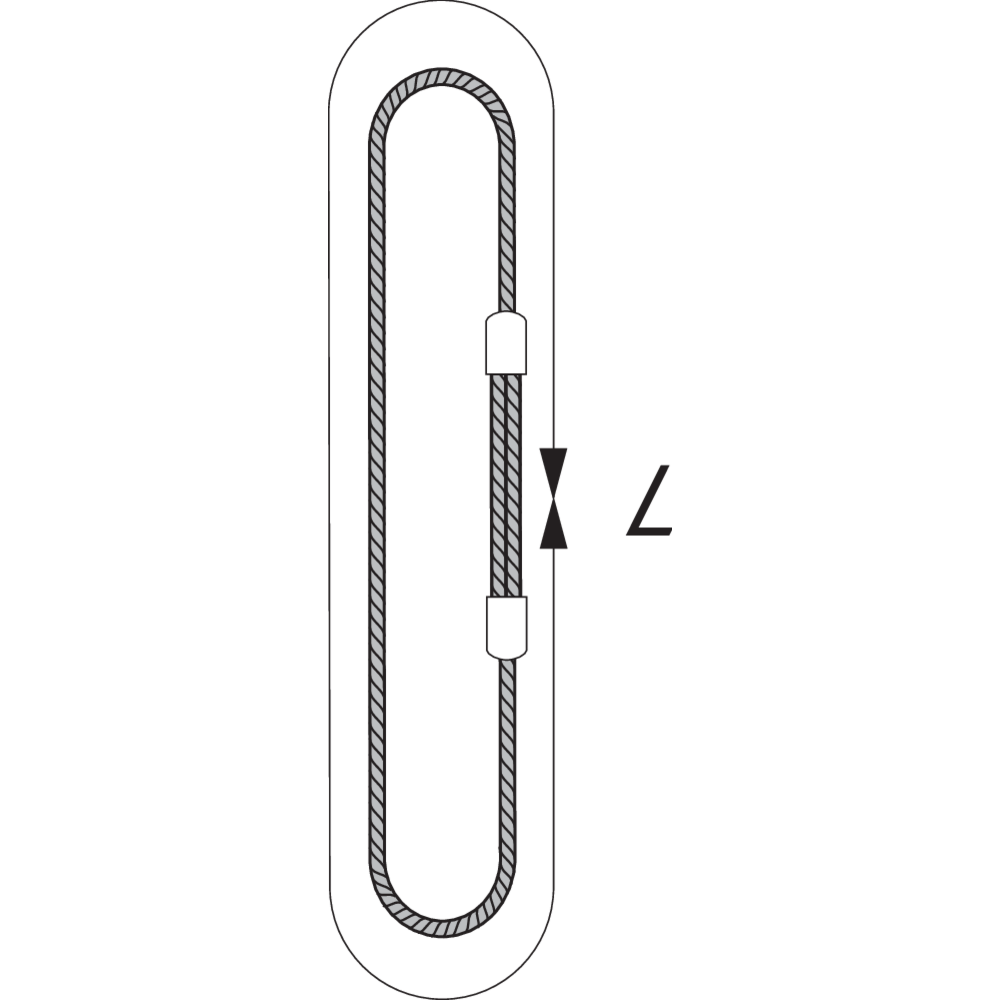

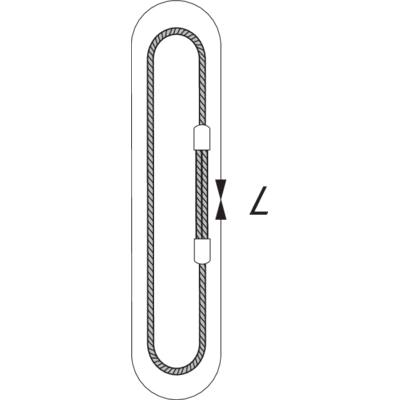

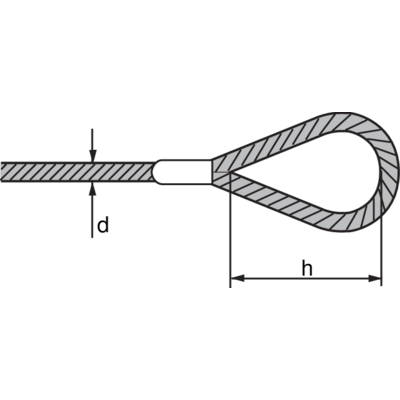

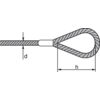

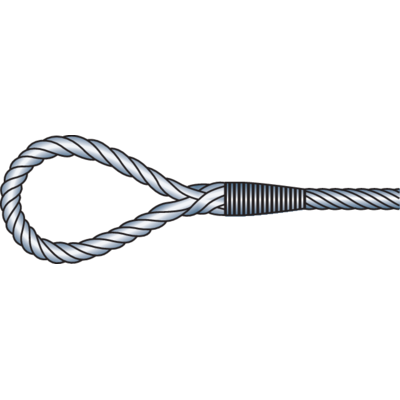

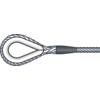

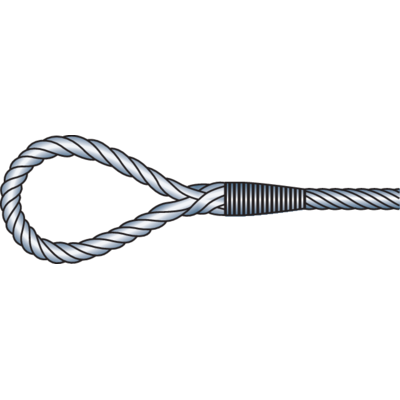

Length of the soft eye

The peripheral length (l) of a soft eye shall be at least four rope lay lengths. CERTEX Svenska apply as standard that the length (h) of the soft eye shall be at least 15 times the rope diameter.

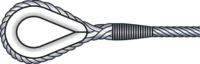

Types of steel wire ropes fittings

The most commonly used rope fittings with indication of remaining percentage of steel wire min breaking force.

|

Pear socket 100% |

|---|---|

|

Spelter socket 100% |

|

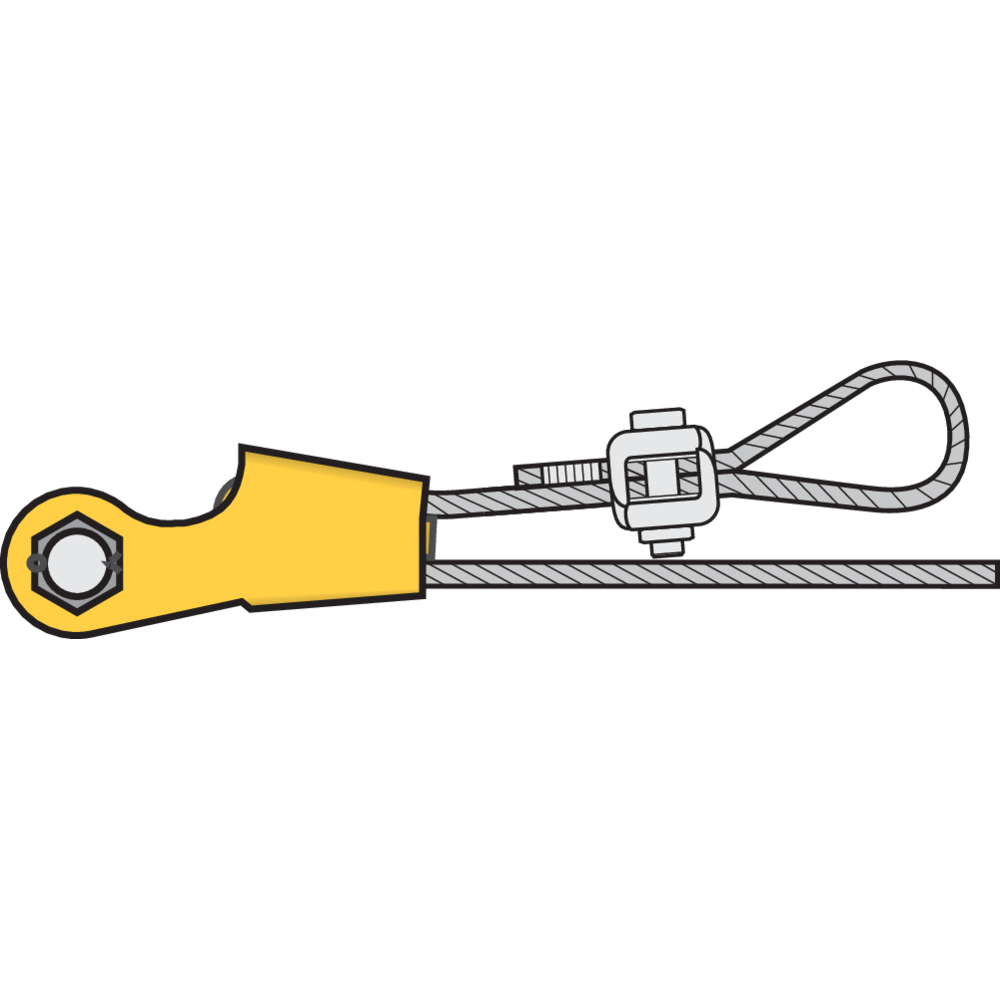

Wedge socket 100% |

|

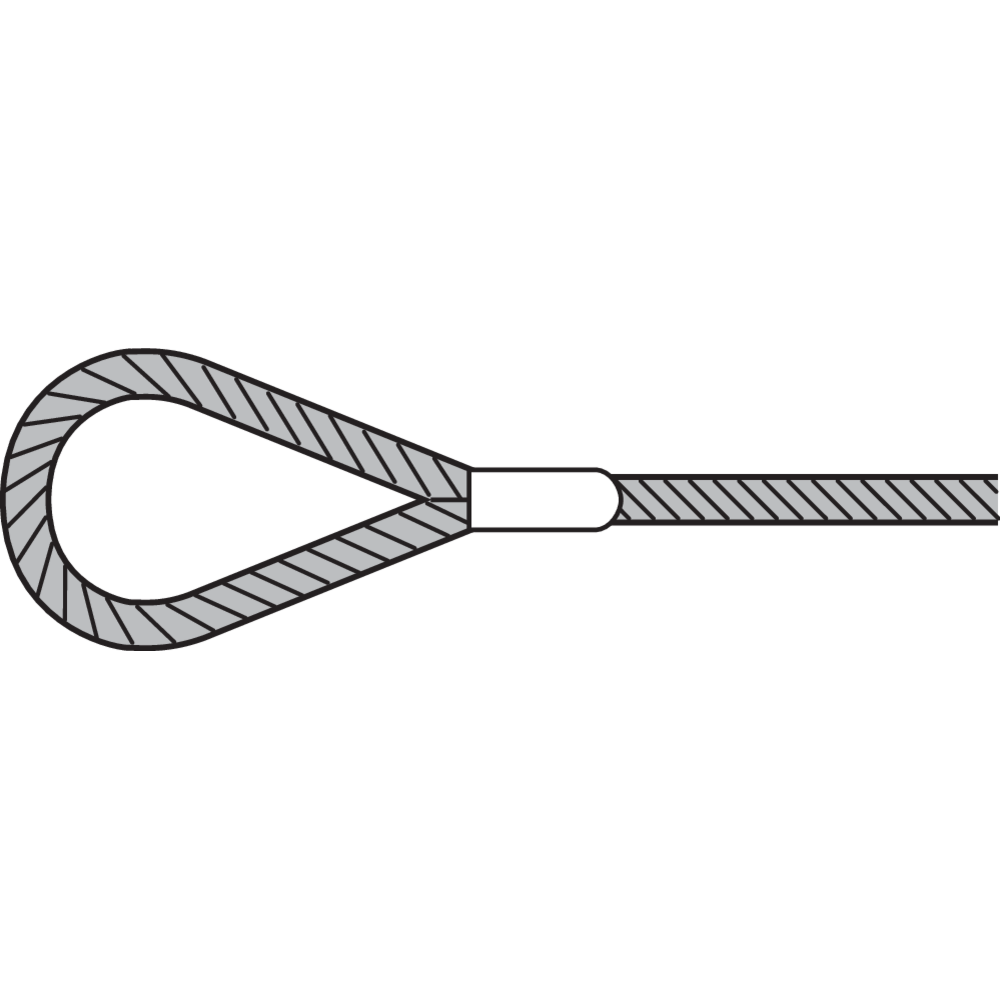

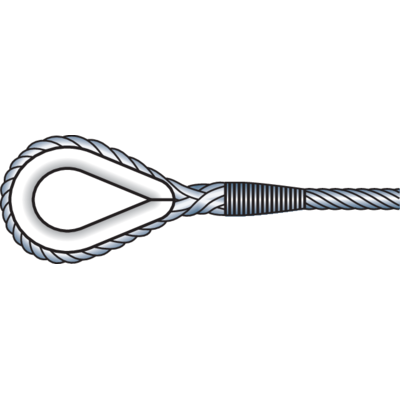

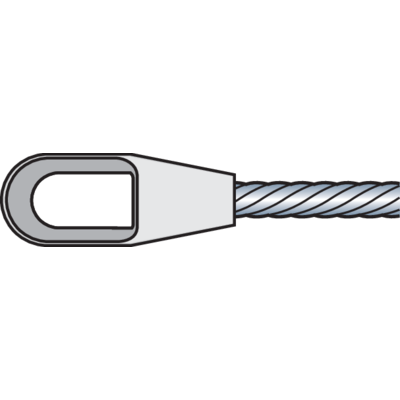

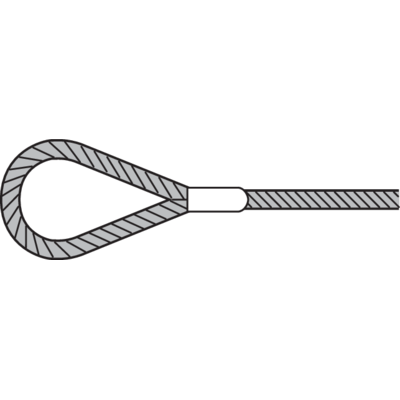

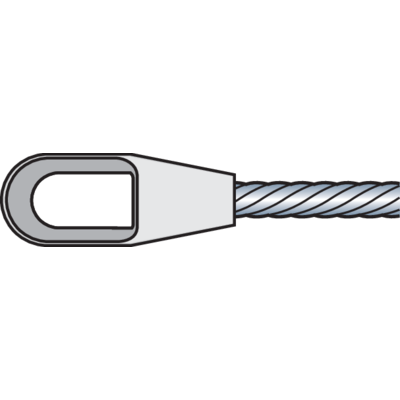

Spliced eye with ferrule 90% |

|

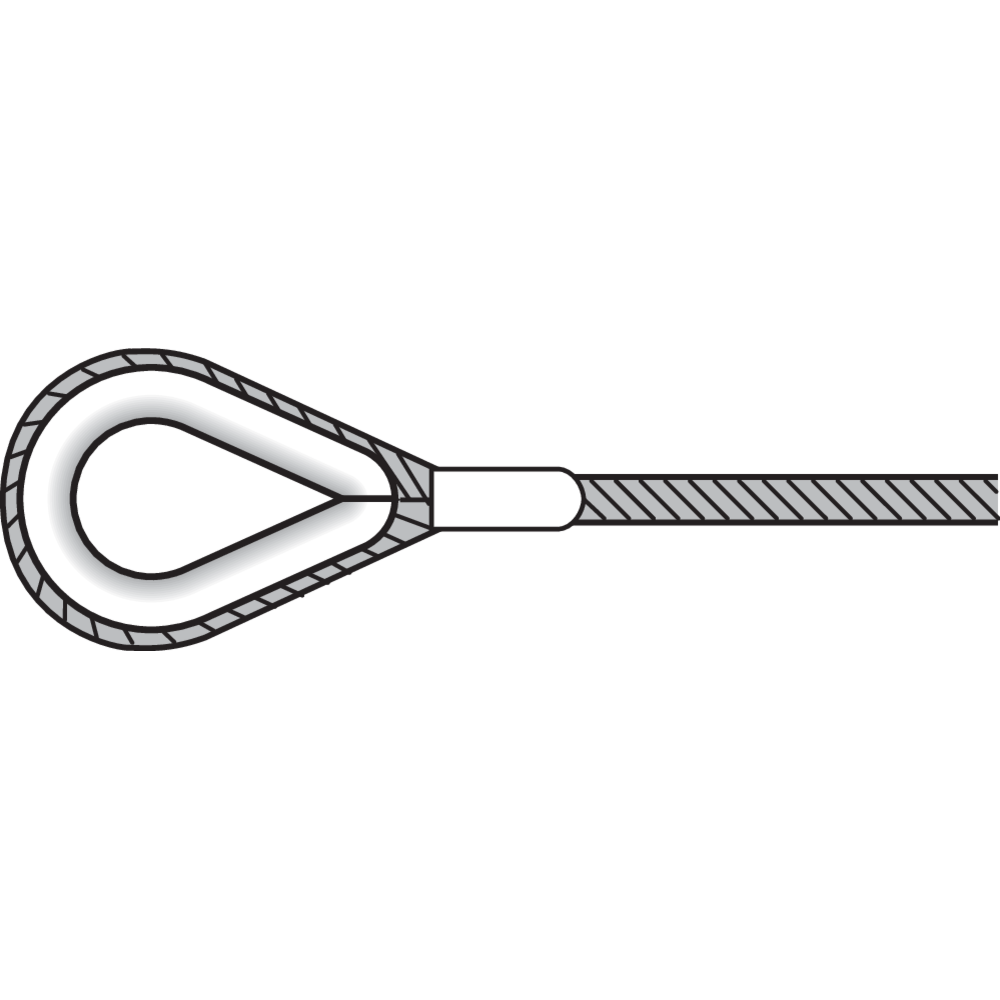

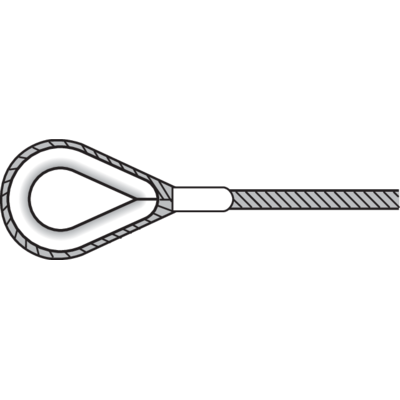

Spliced eye with ferrule and thimble 90% |

|

Spliced eye with ferrule and solid thimble 90% |

|

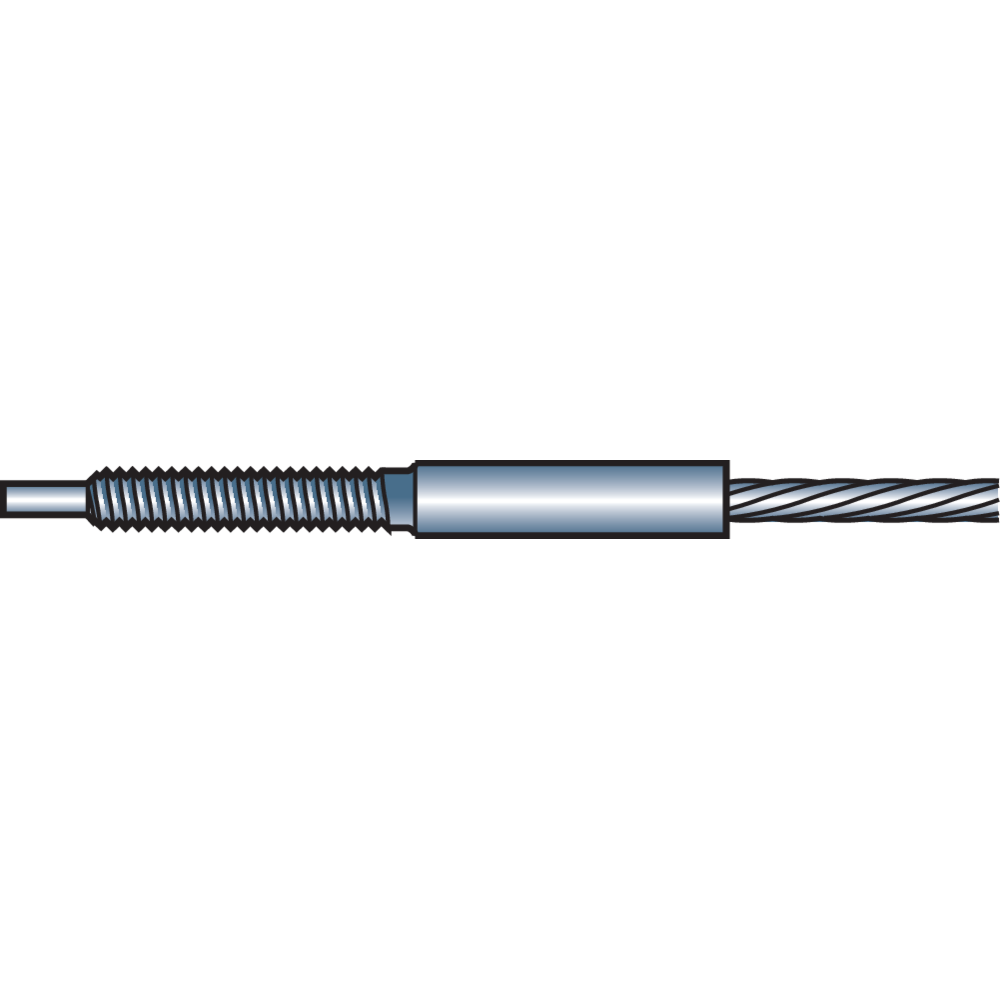

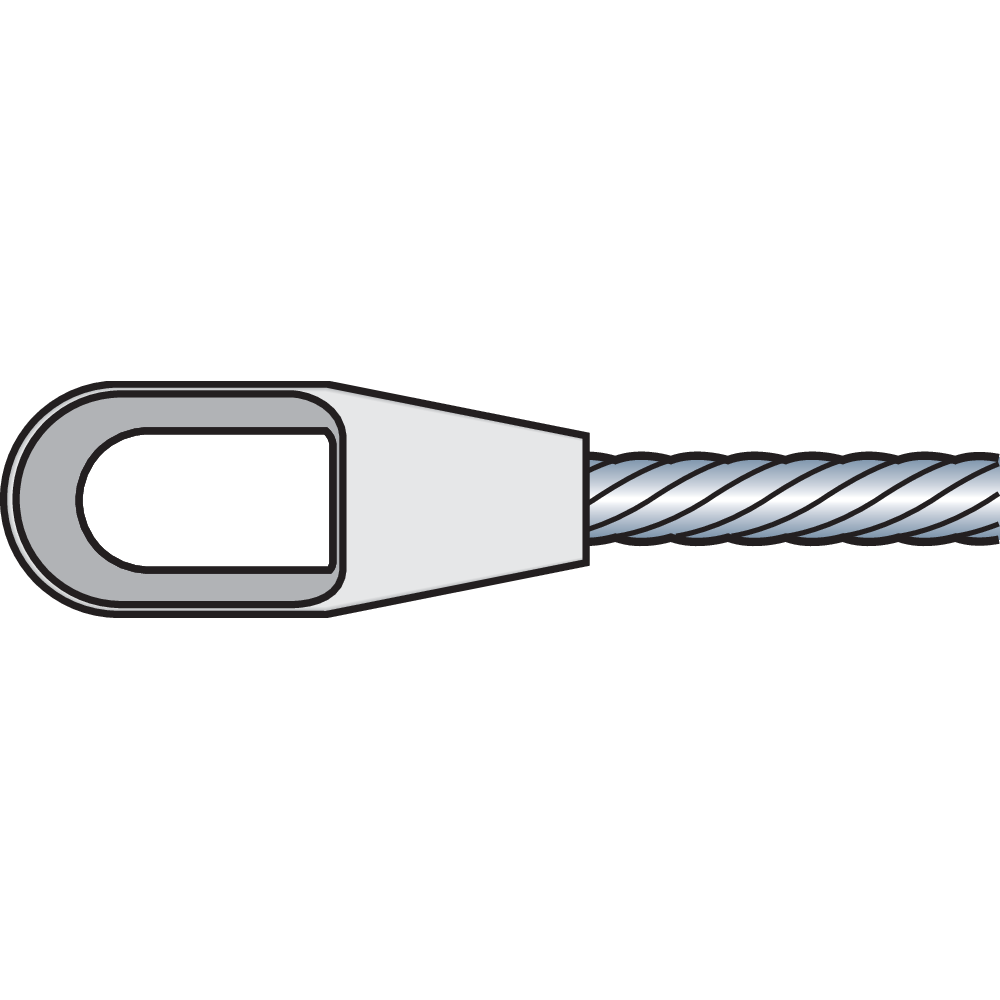

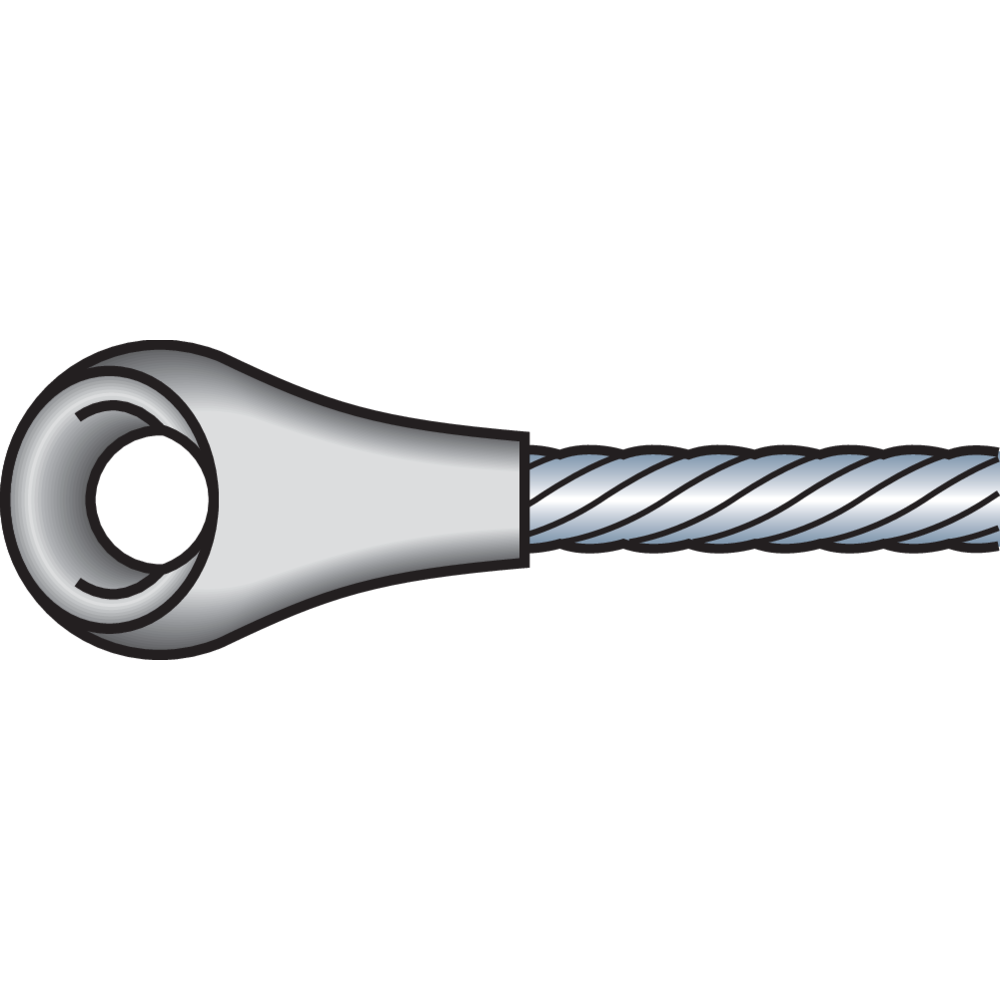

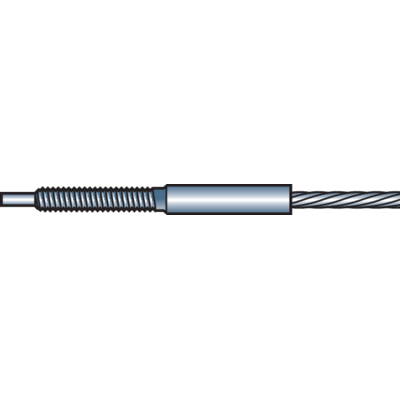

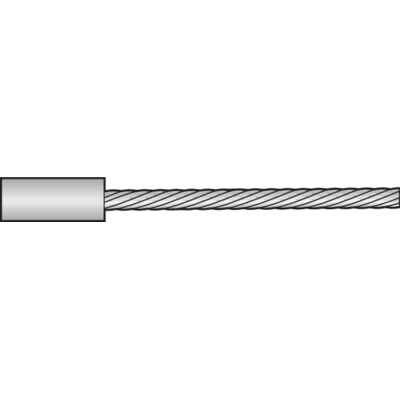

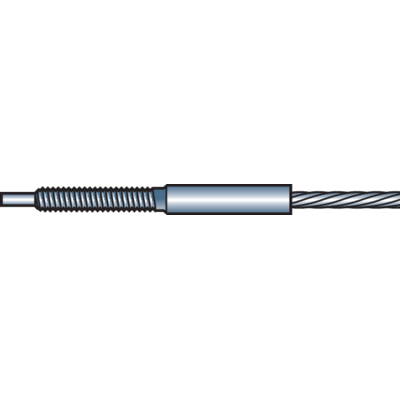

Threaded terminal 90% |

|

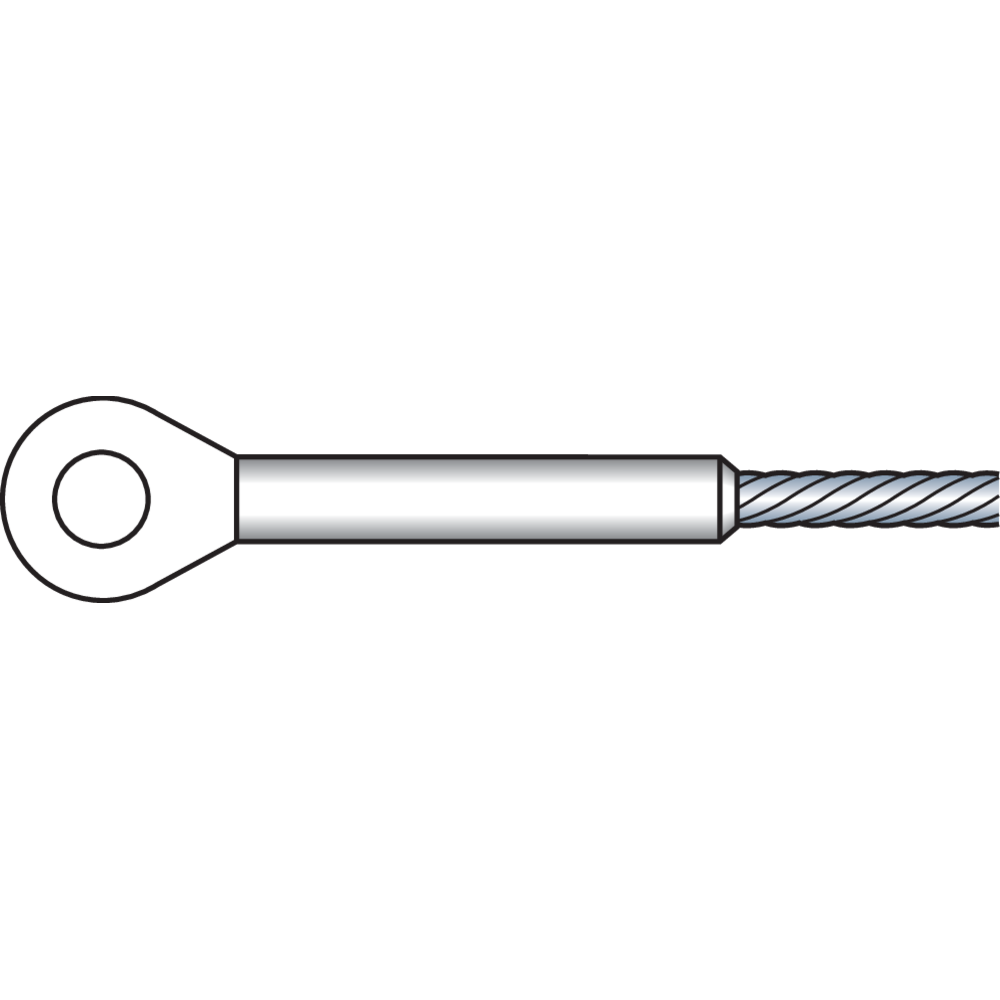

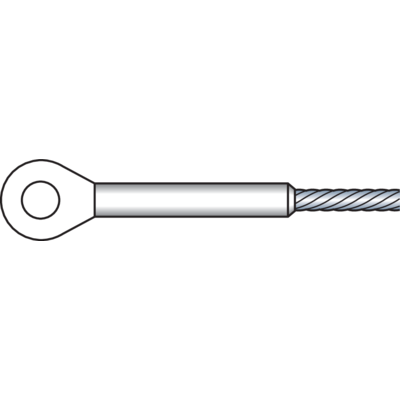

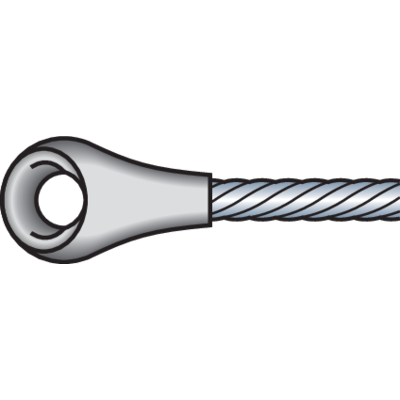

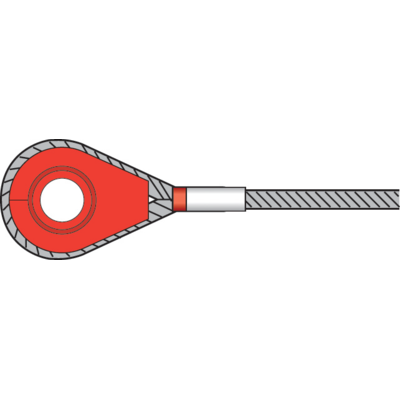

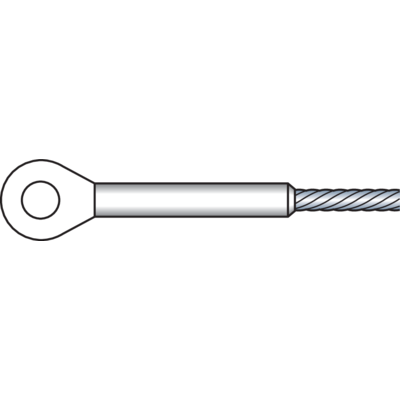

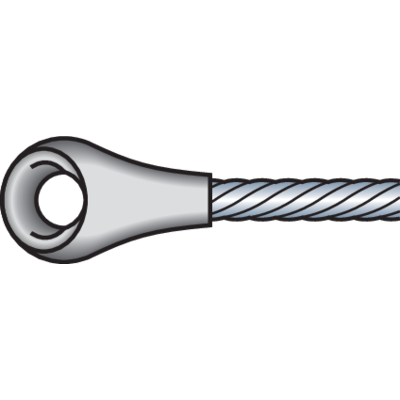

Eye terminal 90% |

|

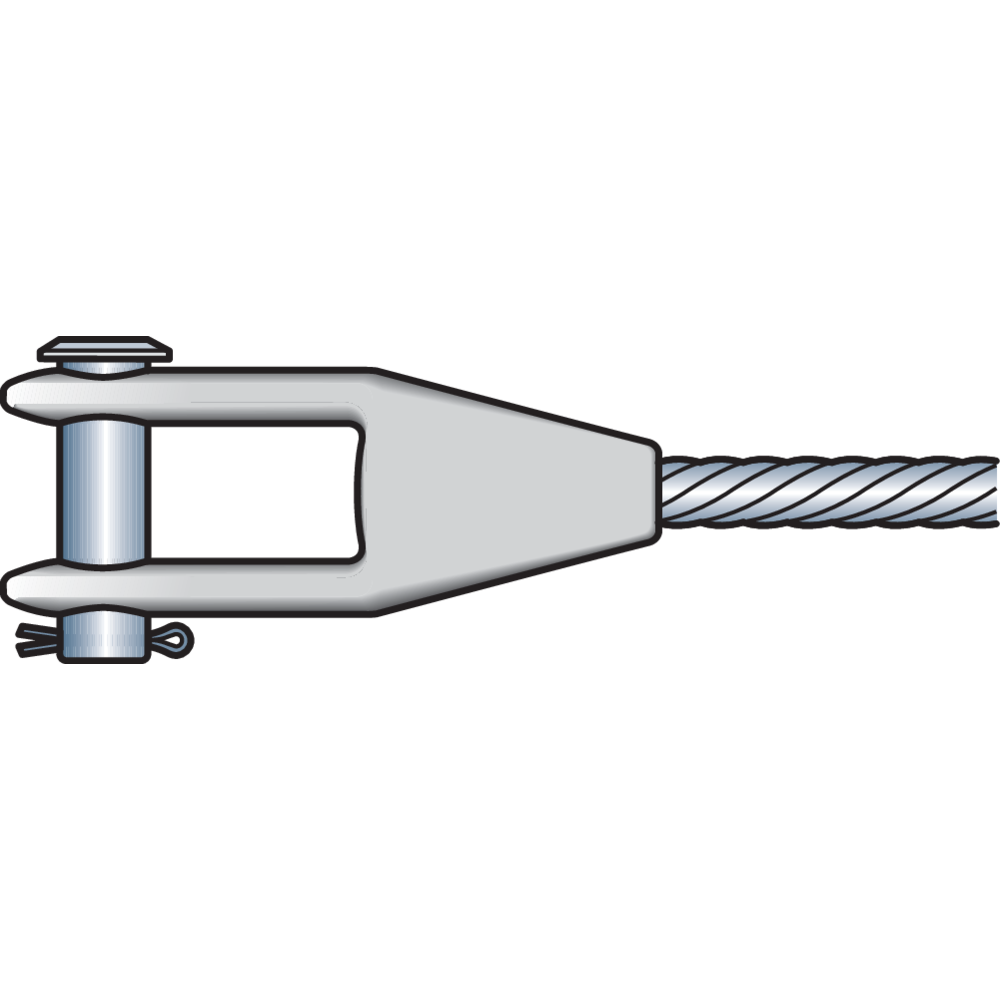

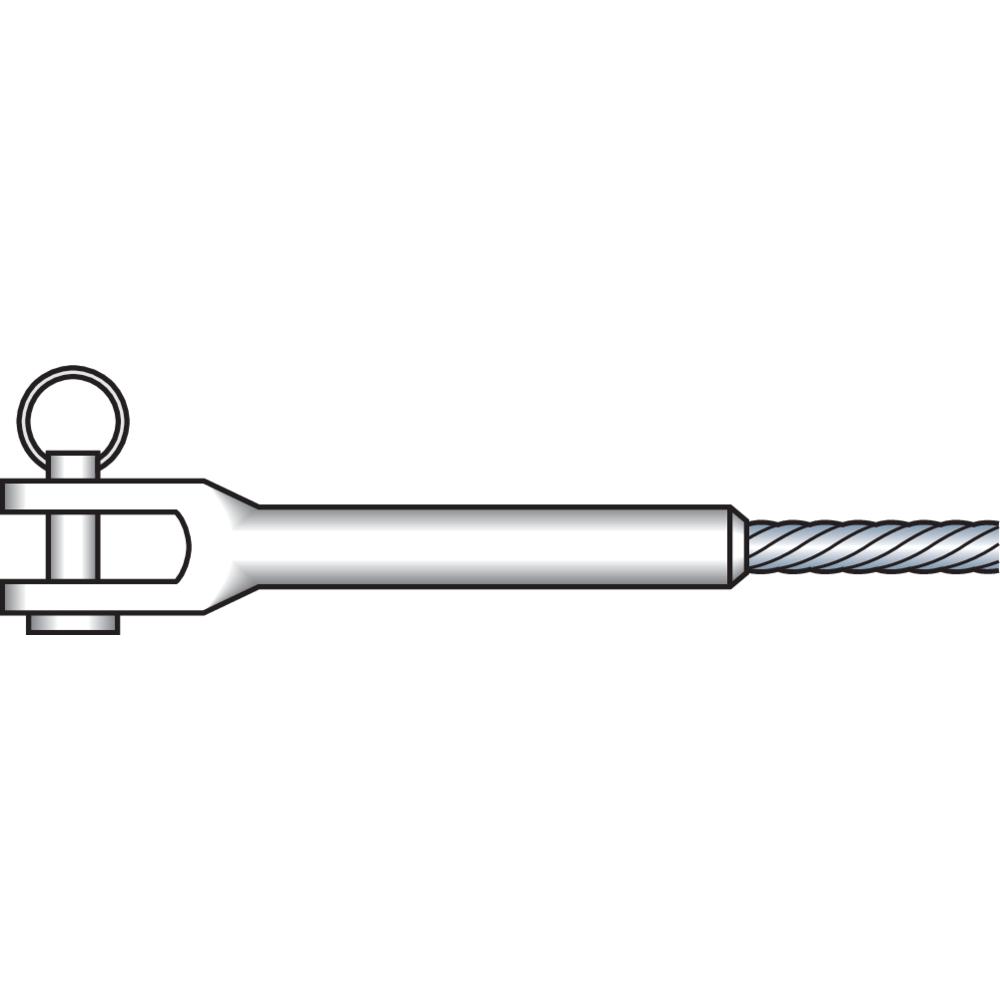

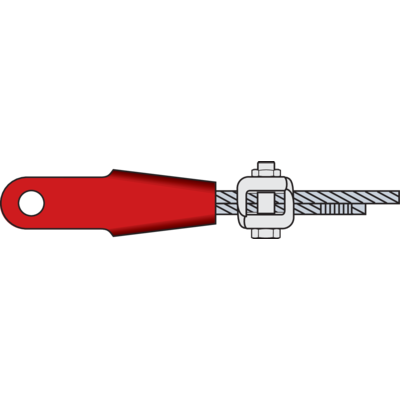

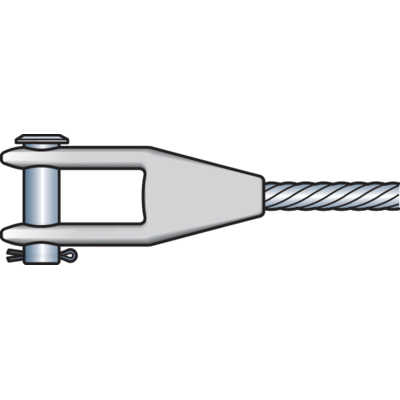

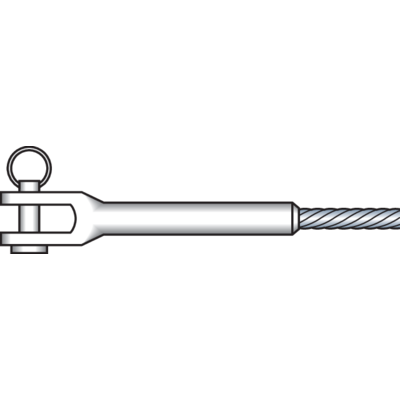

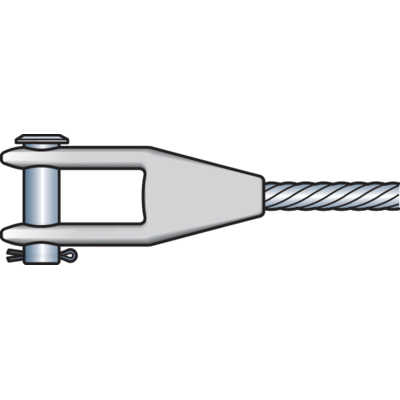

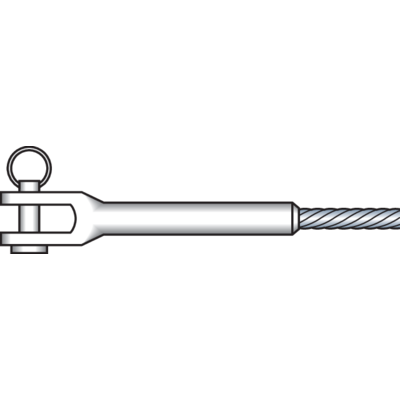

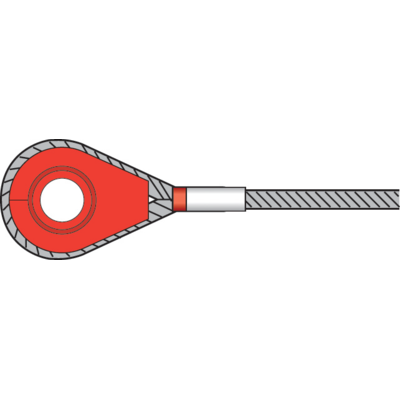

Clevis terminal 90% |

|

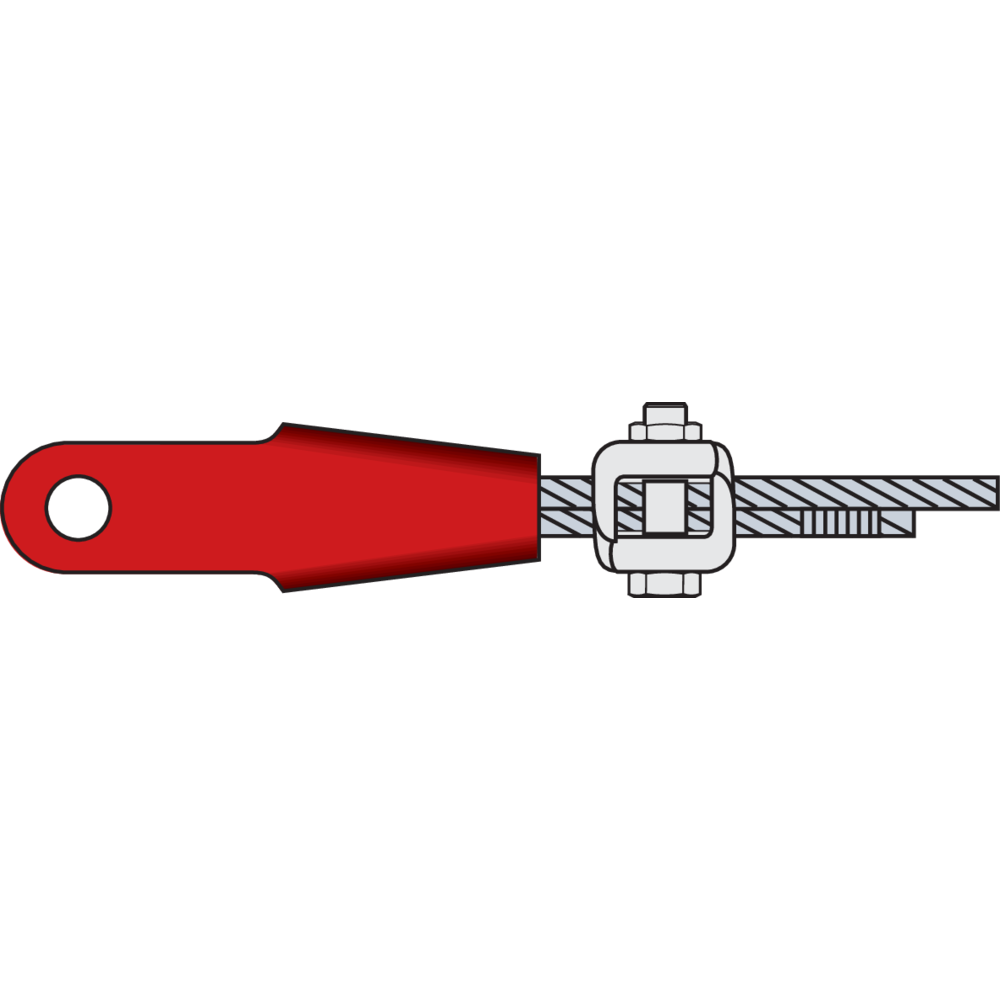

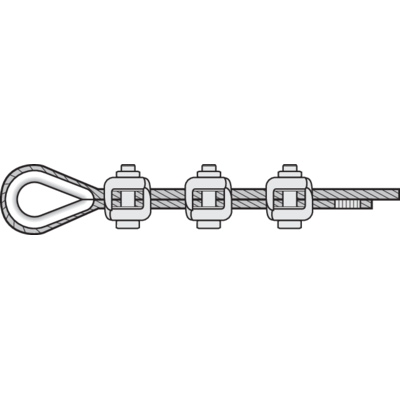

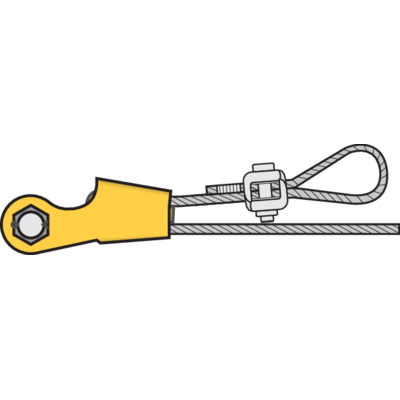

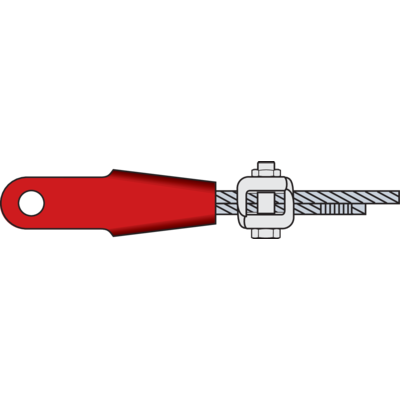

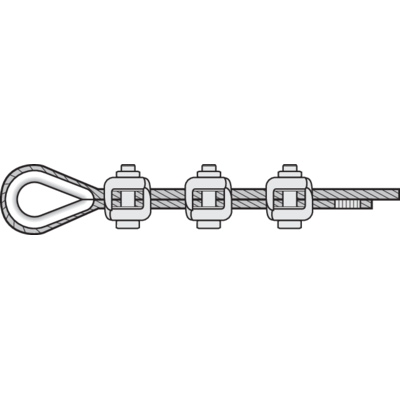

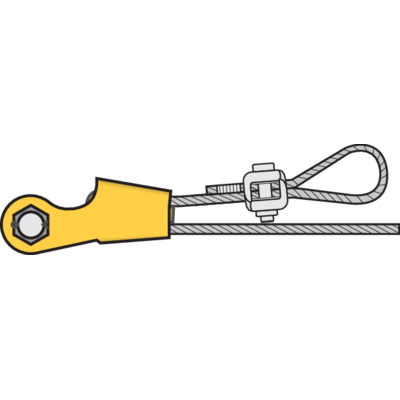

Wire rope clamp 80% |

|

Wedge socket 80% |

|

Wedge socket for elevator 80% |

|

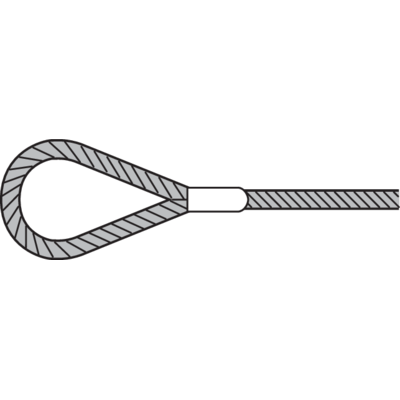

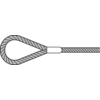

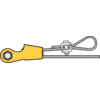

Hand spliced eye 80% |

|

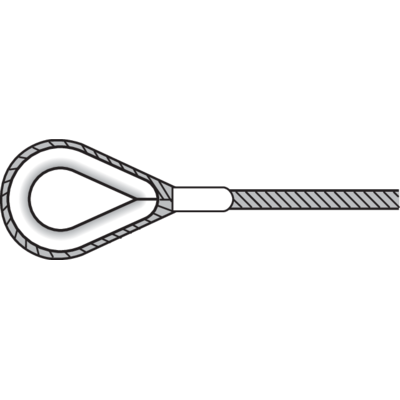

Hand spliced eye with thimble 80% |

|

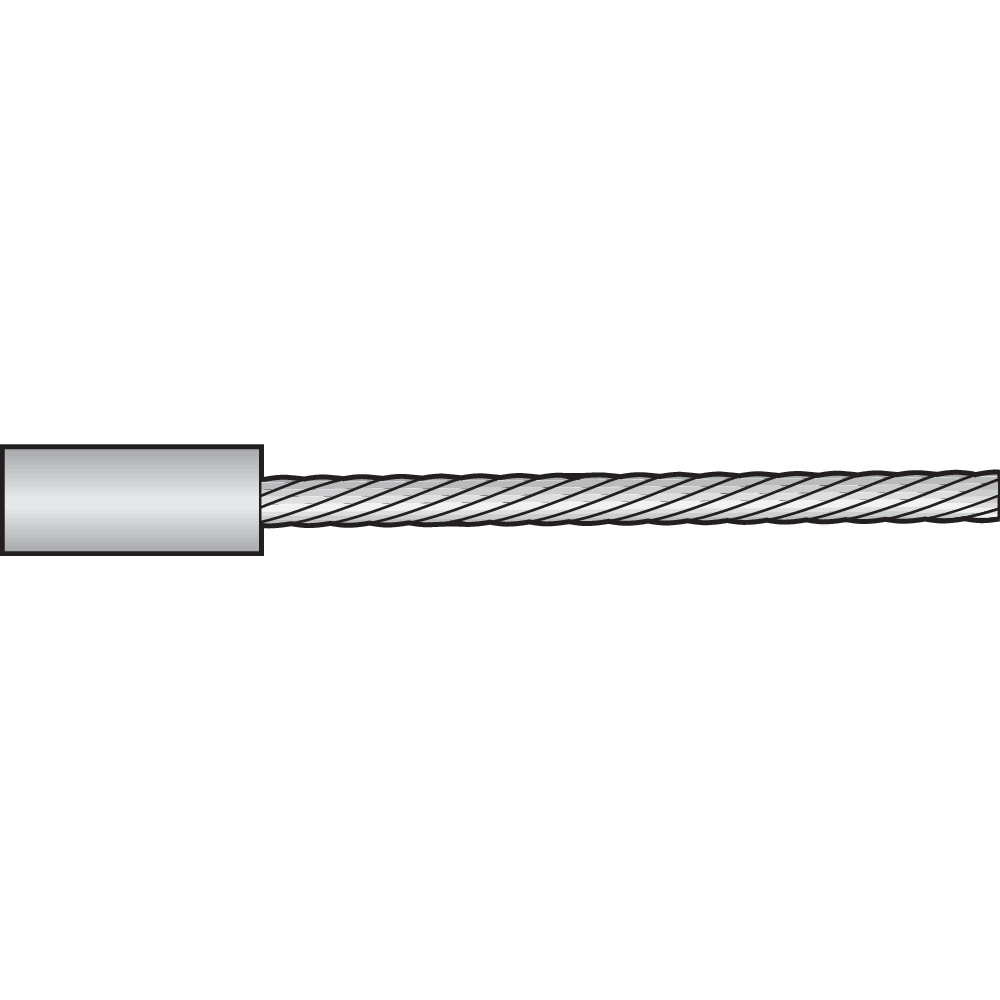

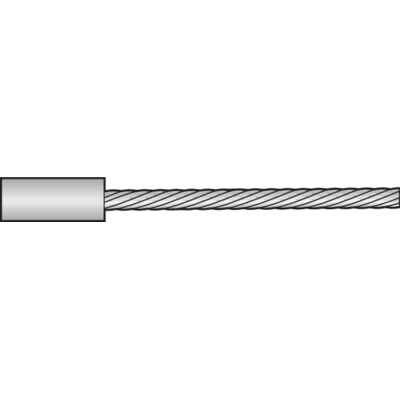

Endstop: Steel 80% Other 50% |

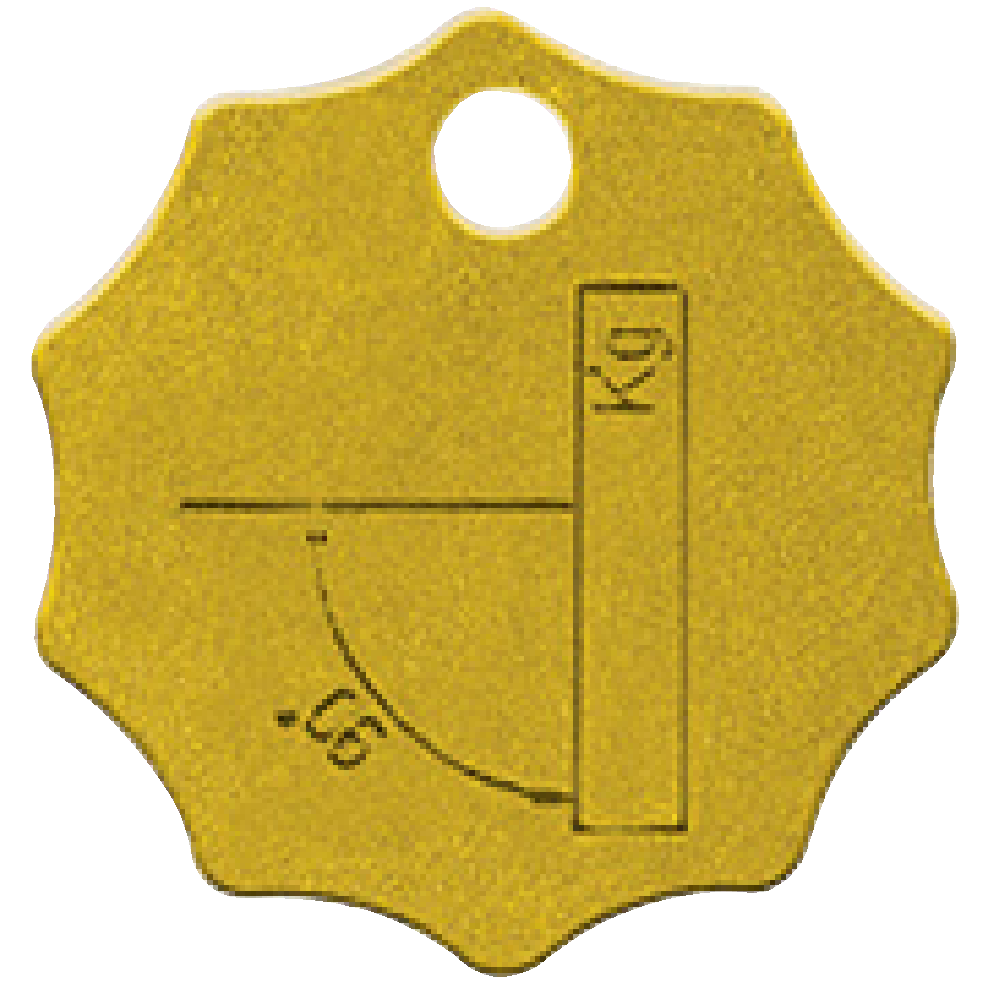

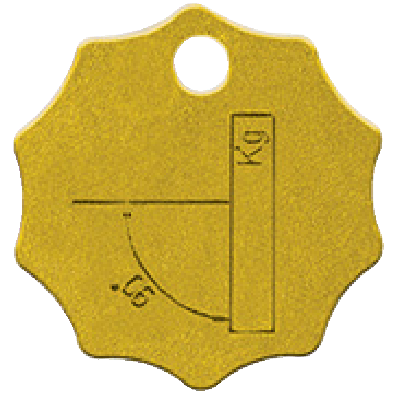

Marking plate

Each sling shall be provided with a marking plate or be marked in the ferrules (single leg and endless slings) with the manufacturer's identifying mark, working load limit (WLL), length, manufacturing date and CE marking.

Working load limit (WLL) for steel wire rope sling

Single leg sling

WLL (ton) = (Fmin x KT) / (Zp x g)

Endless sling (choke)

WLL (ton) = (Fmin x KT x 2 x 0,8) / (Zp x g)

Multi-leg sling

WLL (ton) = (Fmin x KT x KL) / (Zp x g)

Fmin = the minimum breaking force of the rope, in kN.

KT = factor for the efficiency of the termination, for ferrule 0,9 and for spliced 0,8.

KL = the leg factor relating to the number of legs and the angle to the vertical, see WLL-table.

Zp = the coefficient of utilization (working coefficient), with the value 5.

g = 9,81

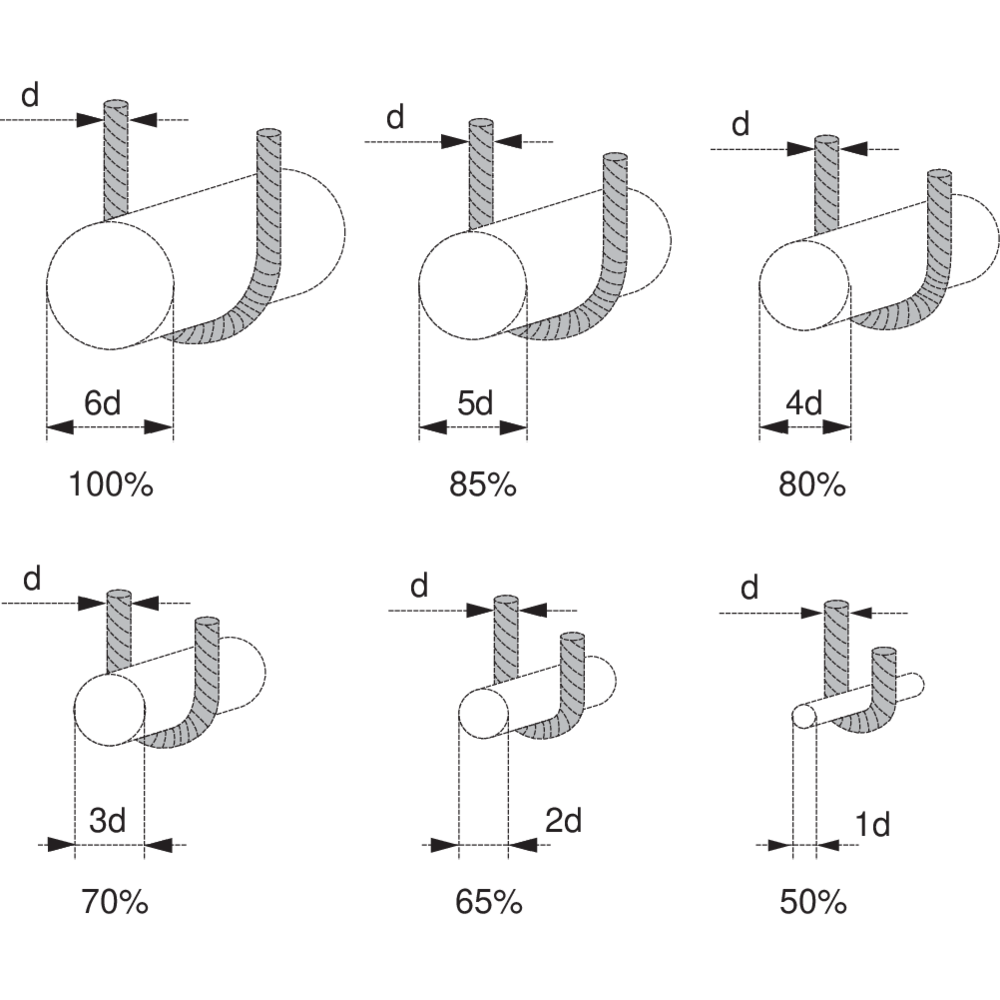

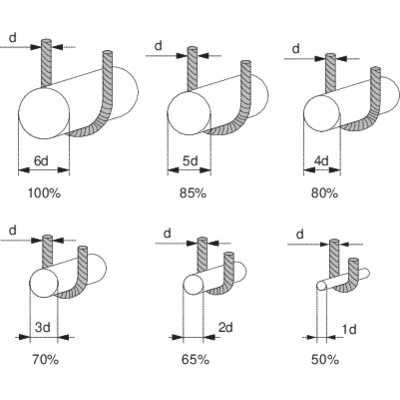

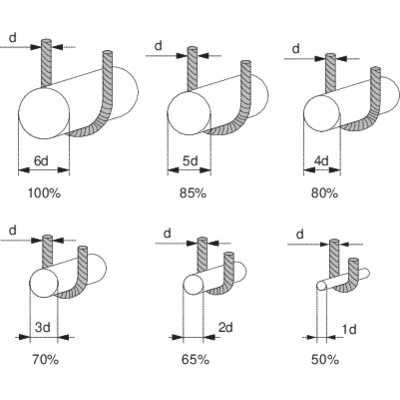

Bending diameters effect on the working load limit (WLL)

CERTEX recommend that consideration will be taken to that the slings capacity will be lower when the bending diameter decreasing. If, for example the rope bends around a bearing point witch have the same diameter as the rope itself the capacity will decrease to the half, see figure.

Temperature Affect on Working Load Limits

Account should be taken of the maximum temperature that can be reached by the wire rope sling in service. This is difficult in practice but underestimation of the temperature should be avoided.

The table below summarises the necessary de-rated working load limits of a sling due to temperature, taking into account the type of rope termination, the ferrule material and the core of the rope.

When wire rope slings are to be used in temperatures below -40 °C CERTEX should be consulted.

The use of wire rope slings within the permissible temperature ranges given in the table does not require any

permanent reduction in working load limit when the rope is returned to ambient temperature.

| Termination type | Ferrule- material | Rope core |

De-rated working load limit expressed as % of WLL of the sling |

|||||

|---|---|---|---|---|---|---|---|---|

| Temperature (t) ºC | ||||||||

| -40 +100 | +101-150 | +150-200 | +200-300 | +300-400 | + 400 | |||

| Ferrule | Aluminium | Fibre | 100 | Do not use | Do not use | Do not use | Do not use | Do not use |

| Ferrule | Aluminium | Steel | 100 | 100 | Do not use | Do not use | Do not use | Do not use |

| Ferrule | Steel | Fibre | 100 | Do not use | Do not use | Do not use | Do not use | Do not use |

| Ferrule | Steel | Steel | 100 | 100 | 90 | 75 | 65 | Do not use |

| Splice | - | Fibre | 100 | Do not use | Do not use | Do not use | Do not use | Do not use |

| Splice | - | Steel | 100 | 100 | 90 | 75 | 65 | Do not use |

| Socket | zinc/alloy | Fibre | -40 - 80ºC 100% | |||||

| Socket | zinc/alloy | Steel | -40 - 120ºC 100% | |||||

| Socket | 2-component | Fibre | -50 - 80ºC 100% | |||||

| Socket | 2-component | Steel | -50 - 80ºC 100% | |||||

Acidic conditions

Wire rope slings should not be used either immersed in acidic solutions or exposed to acid fumes.

Chemical affect

CERTEX should be consulted in case the slings are to be exposed to chemicals combined with high temperature.

Do you have any questions?

If you have any additional questions, please contact us and we will answer you.