What to know about safe use of chain slings?

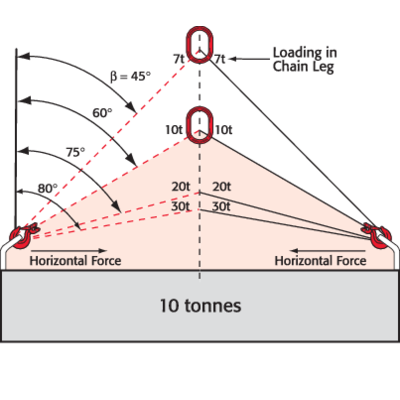

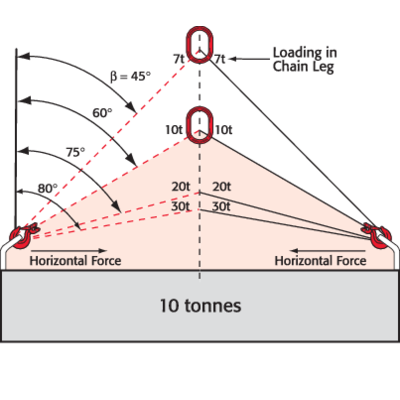

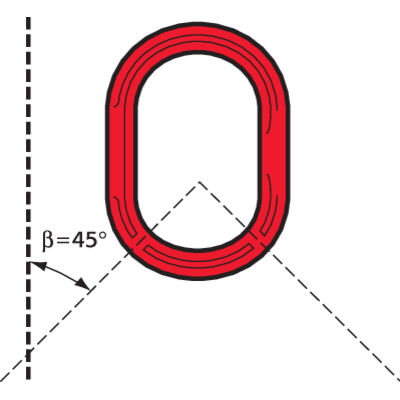

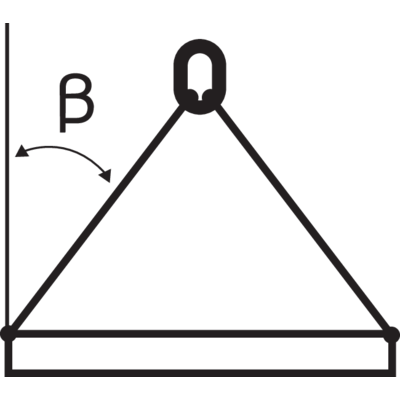

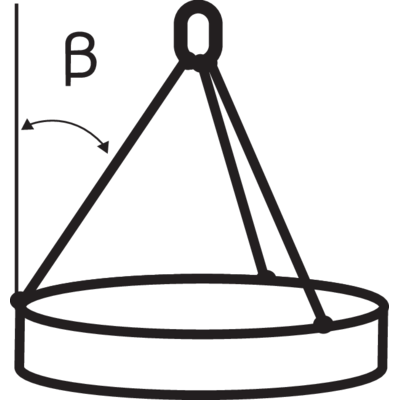

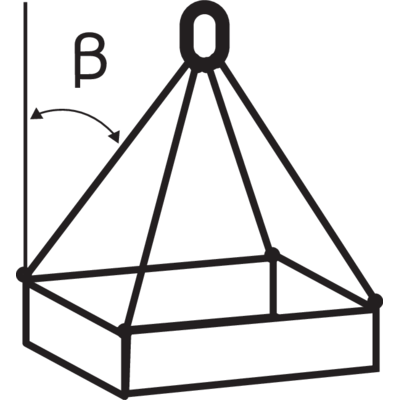

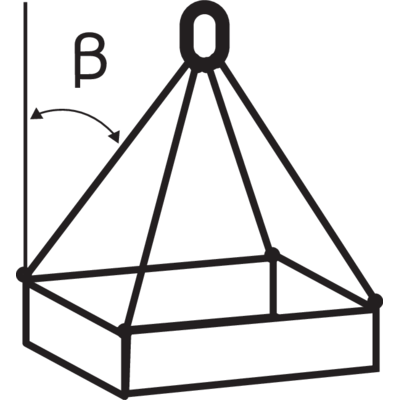

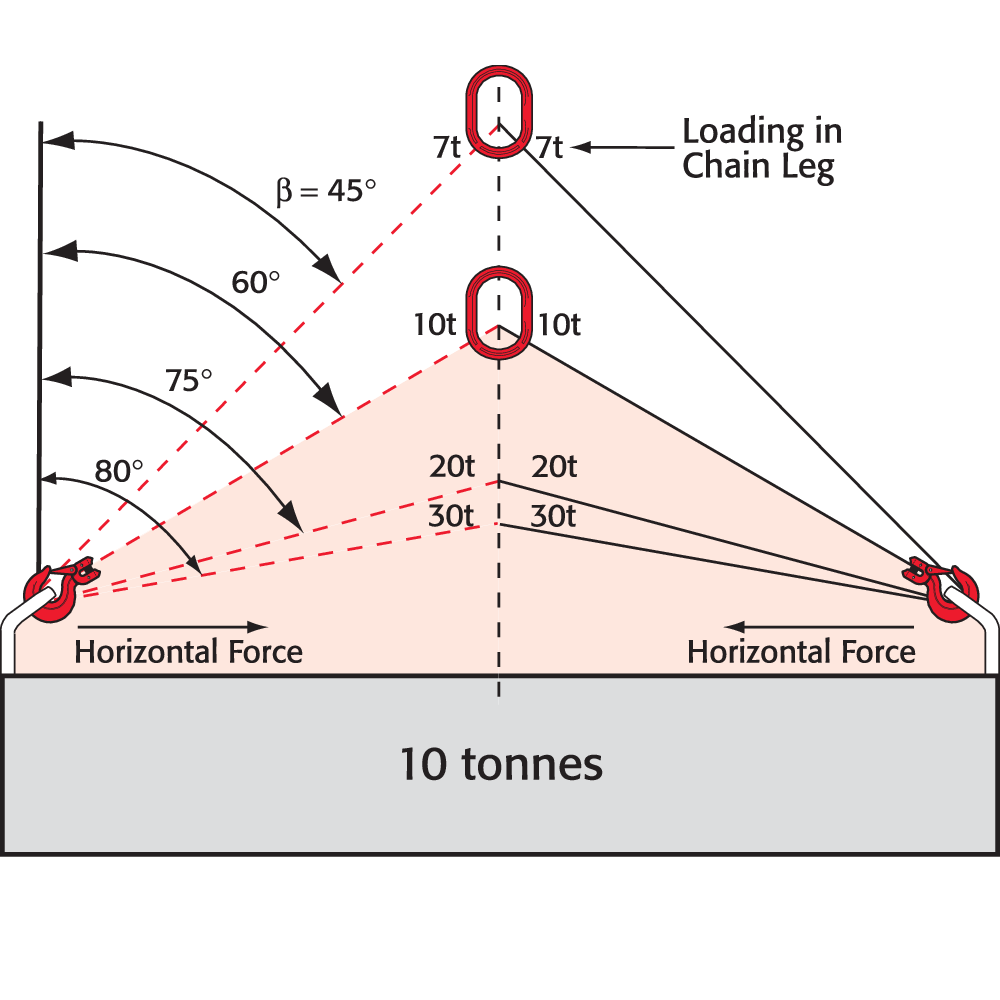

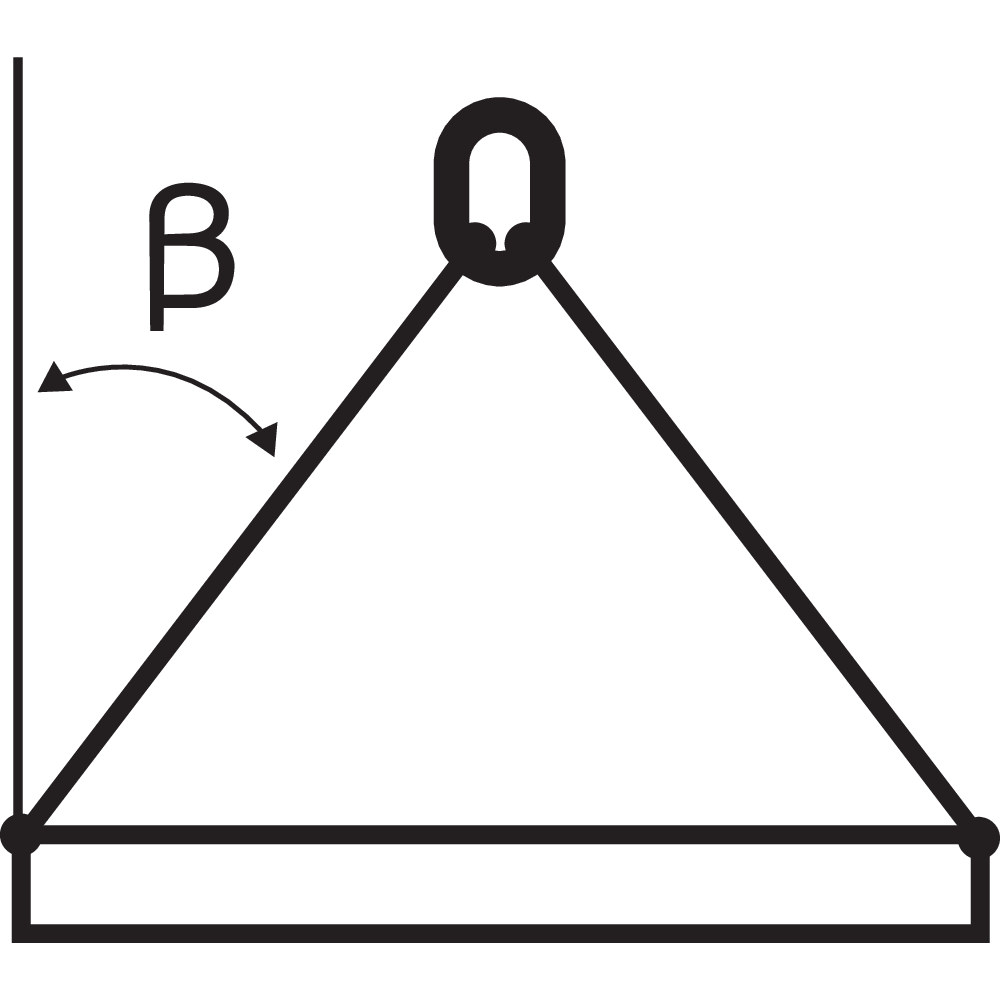

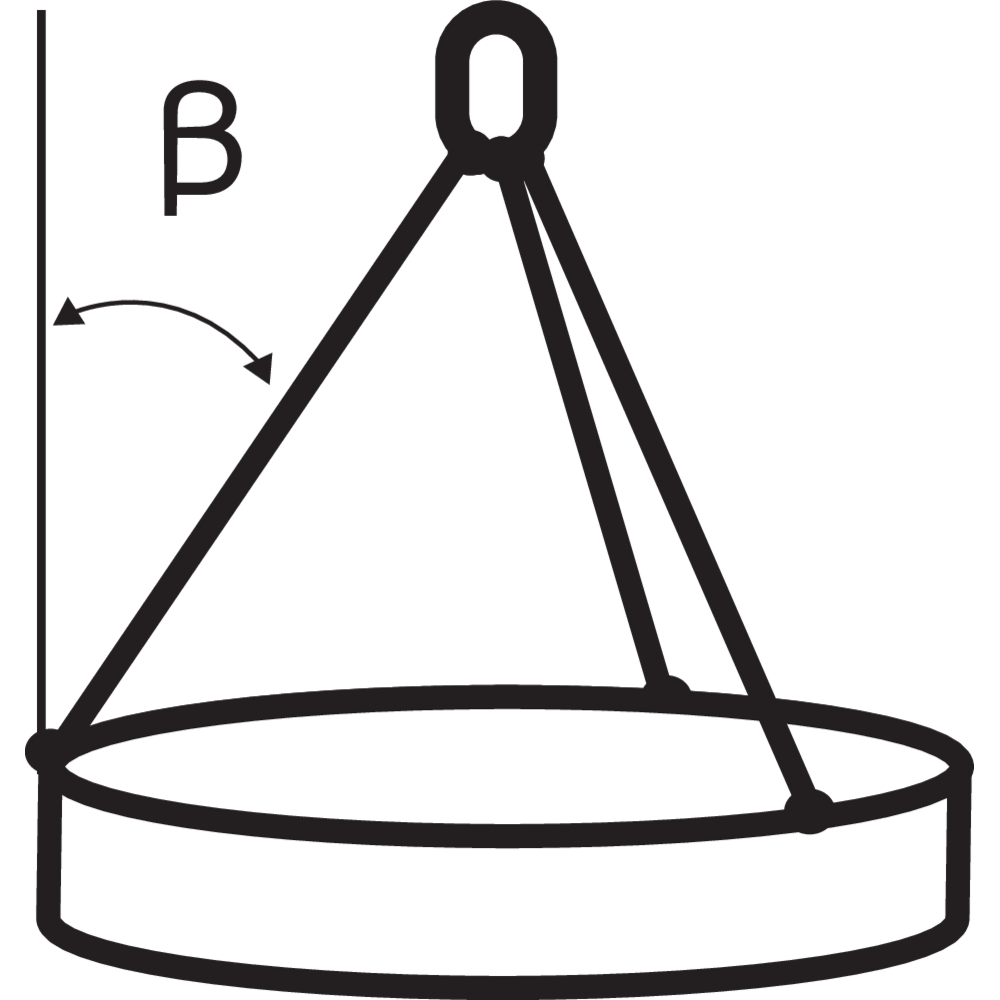

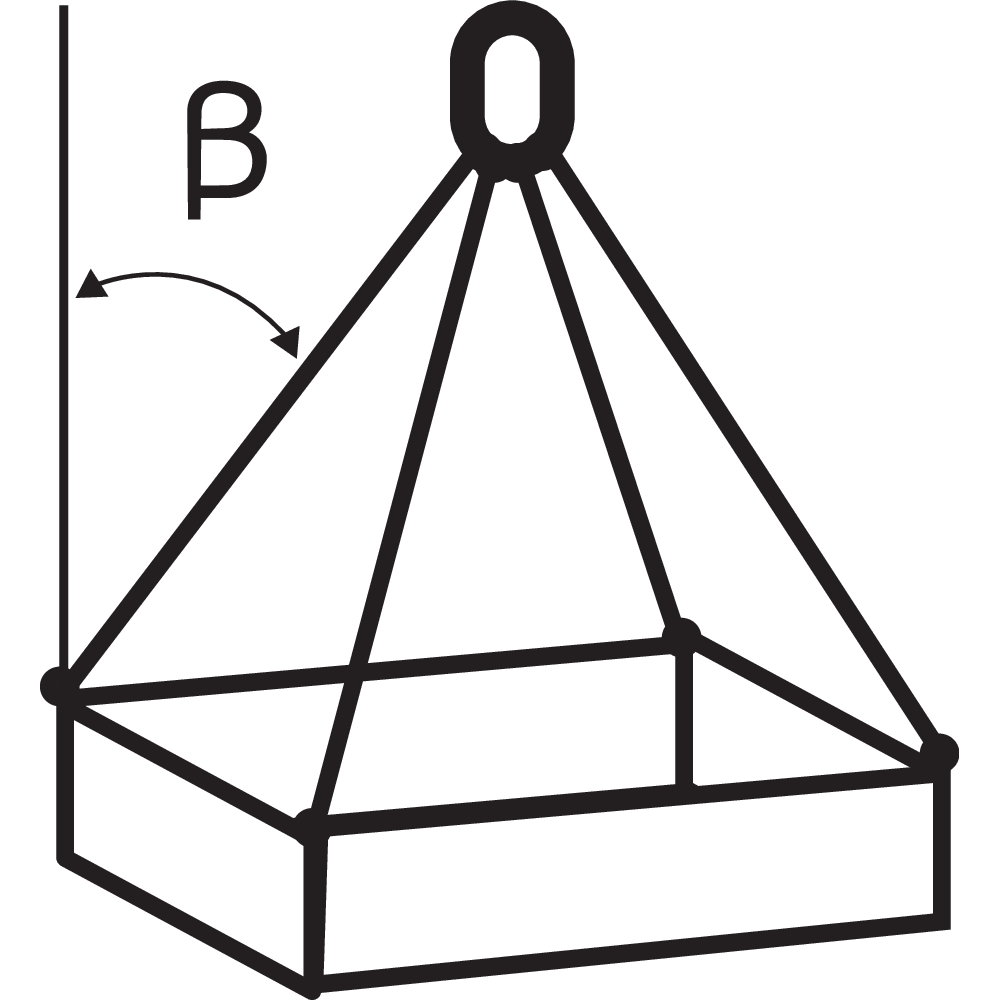

Restrictions on the Angle of Use

All multi-leg chain slings exert a horizontal component of force, which increases as the angle from the vertical becomes greater.

No chain sling should be used if the angle from the vertical exceeds 60°, as beyond this point the forces in the legs drastically increase.

DO NOT USE MULTI-LEG CHAIN SLINGS AT ANGLES WITHIN THE SHADED AREA. Angles of less than 15° should also be avoided as these can lead to the load becoming unstable.

Limitations on Use

Due to risk of embrittlement chain slings should not be used in acid or caustic solutions nor in heavily acidic or caustic laden atmospheres. In uncertain conditions consult CERTEX.

Chain slings must not be heat treated, galvanised, plated, coated or subject to any process involving heating or pickling. Each of these processes can have dangerous effects and will invalidate the manufacturers certificate.

Chain slings may be used in temperatures down to -40 o C with no reduction in the working load limit. The use of KUPLEX chain slings within the permissable temperature range in the table shown does not require any permanent reduction in working load limit when the chain sling is returned to normal temperatures. A sling accidentally exposed to temperatures in excess of the maximum permissable should be withdrawn from service immediately and returned to CERTEX for thorough examination.

When using chain slings in exceptional hazardous conditions, the degree of hazard should be asssessed by a competent person and the working load limit adjusted accordingly. Examples include the lifitng of persons and the lifting of potentially dangerous loads such as molten metals, corrosive materials or fissile material and certain offshore activities.

Temperature Limitations

| Sling Temperature | Reduction in Working Load Limit | |

|---|---|---|

| Grade 8 | Grade 10 | |

| -40 0 C - 200 0 C | NONE | NONE |

| 200 0 C - 300 0 C | 10% | DO NOT USE |

| 300 0 C - 400 0 C | 25% | DO NOT USE |

| Above 400 0 C | DO NOT USE | DO NOT USE |

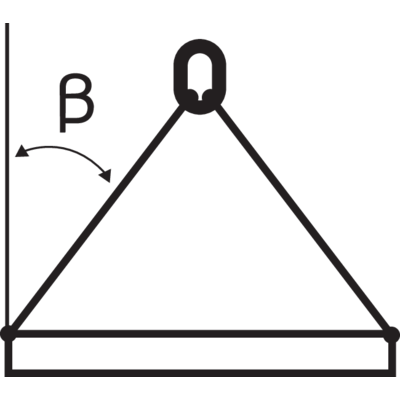

Calculation of working load limit (WLL) for chain slings

When the exact information about weight, lifting angle and position of the centre of gravity is known, you are able to calculate the working load limit using the trigonometric method as follows:

2-leg sling

WLL (ton) = 2 x WLL for single leg sling x cos ß.

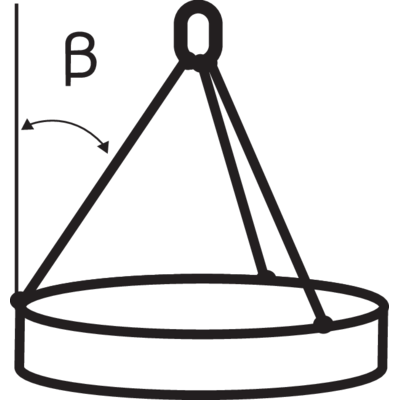

3-4-leg sling

WLL (ton) = 3 x WLL for single leg sling x cos ß.

Note: If the load is unform on all 4 legs in a sling the following formula can be used in exceptional cases:

WLL (ton) = 4 x WLL for single leg sling x cos ß.

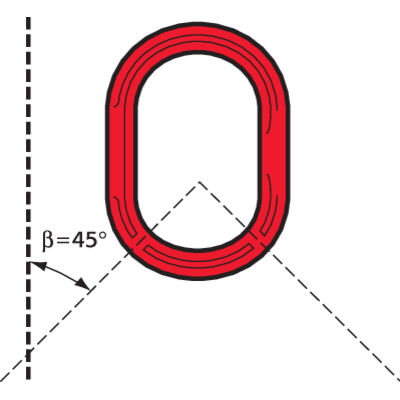

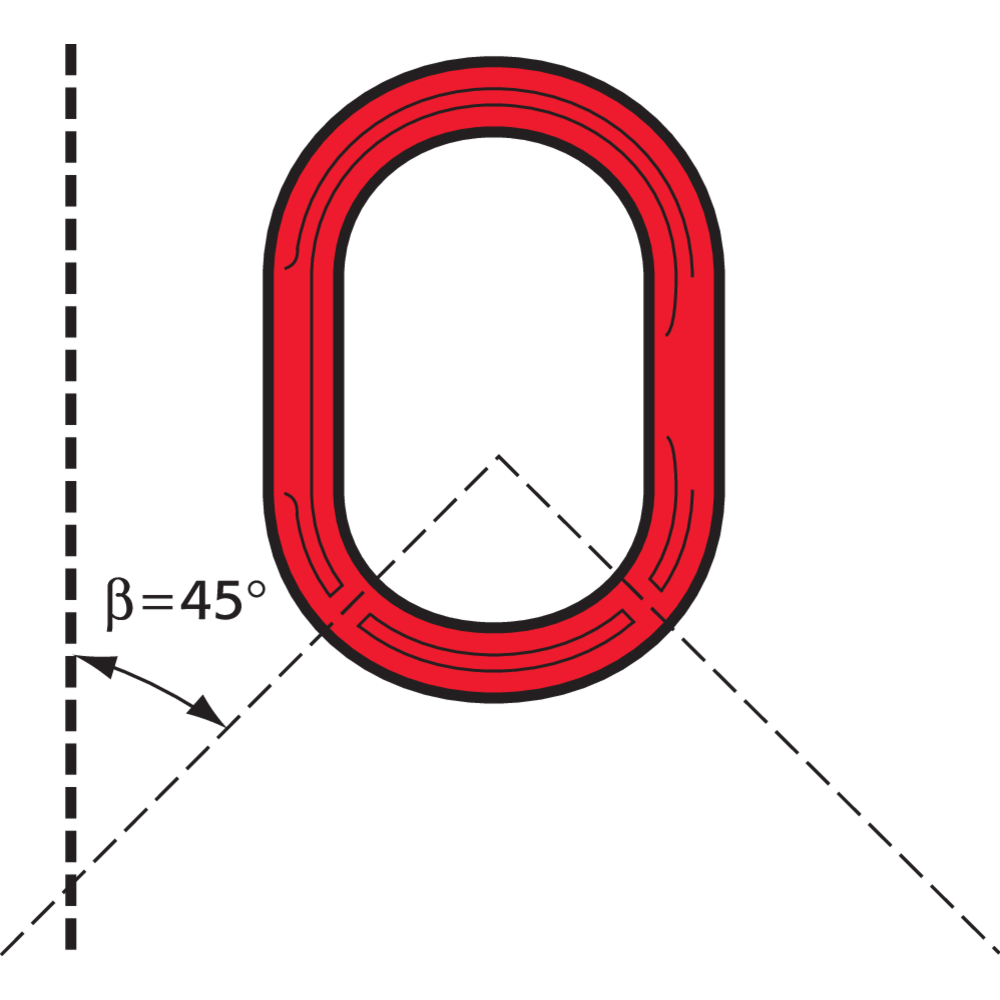

ß = the legs angle against the vertical surface.

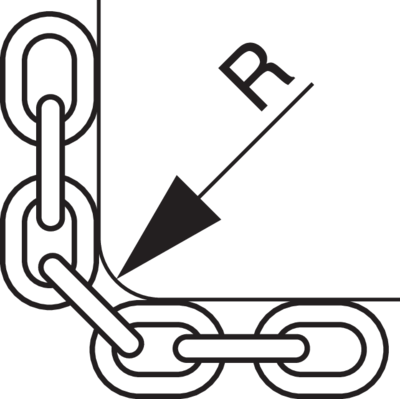

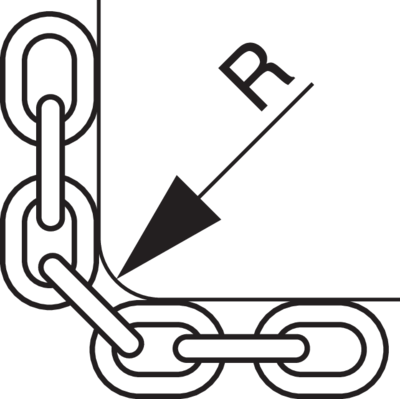

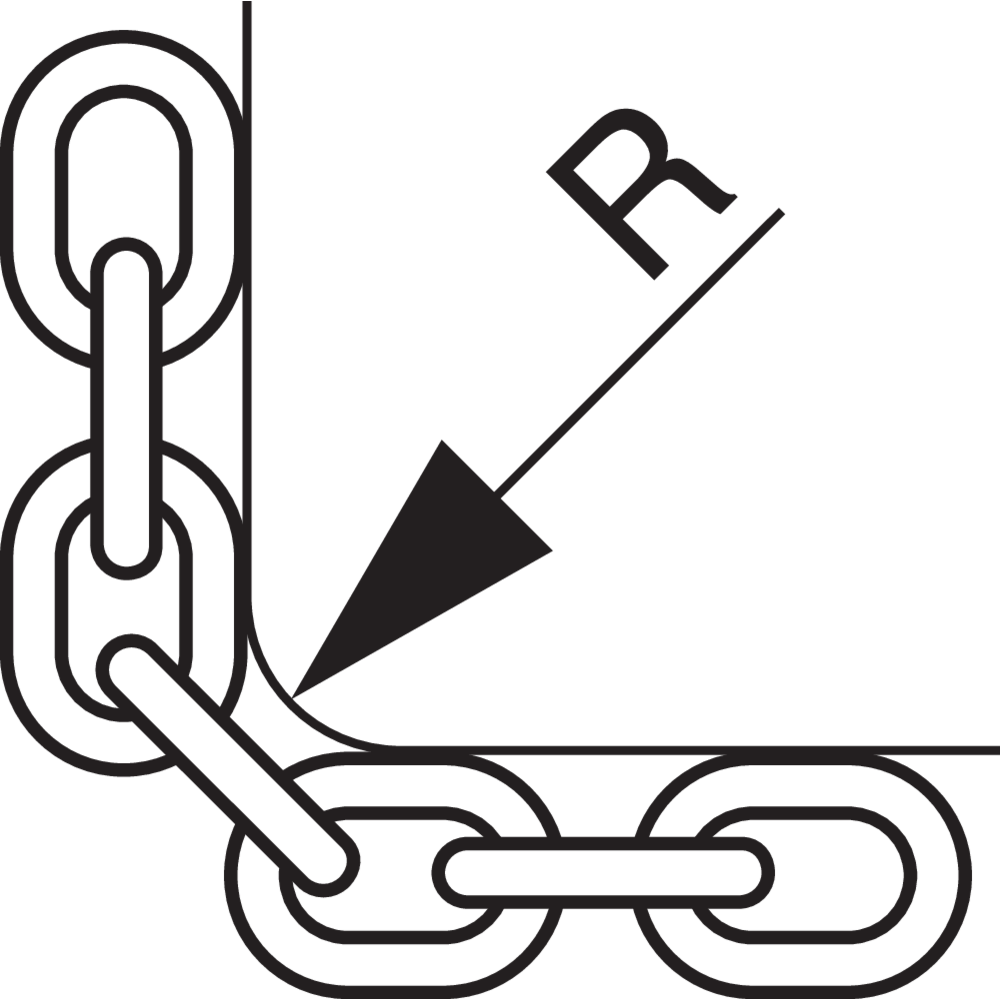

Sharp edges

Edge protectors should be used to prevent sharp edges from damaging the lifting equipment. As a general rule the radius (R) of the edge should be > 2x the chain diameter. When lifting with chain directly on lugs it is recommended that lug diameter greater than 3x the pitch of the chain should be used. If a lug diameter is less than this, the WLL must be reduced by 50%.

| Edge R | R > 2x chain Ø | R > than chain Ø | R = chain Ø |

|---|---|---|---|

| Celtspējas koeficients | 1 | 0,7 | 0,5 |

Multi Leg Chain Slings

The working load limit of any master link should be at least equal to that of the sling. The working load limit of any intermediate link fitted to a 3-leg or 4-leg sling should be at least equal to 1,6 times the WLL of the current chain.

WARNING! If the sling is to be used in an anticipated lift with a lifting angle less then (ß) 45° and with a higher working load limit than usual, it should be specified at time of order.

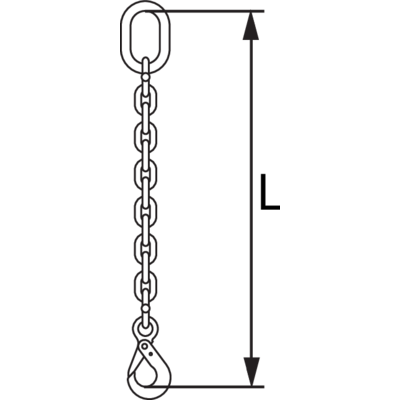

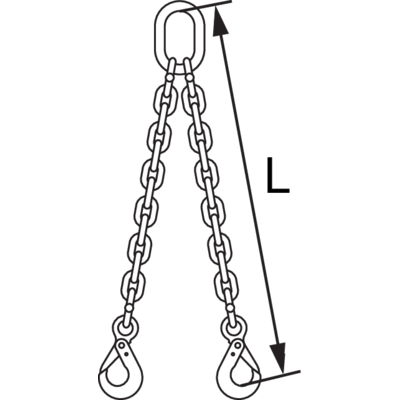

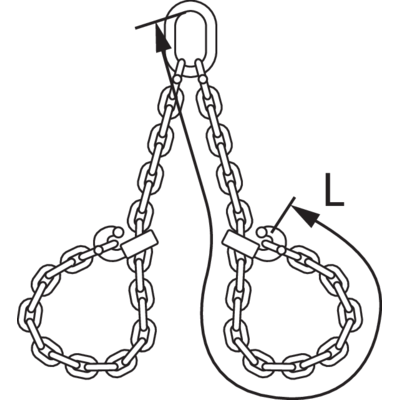

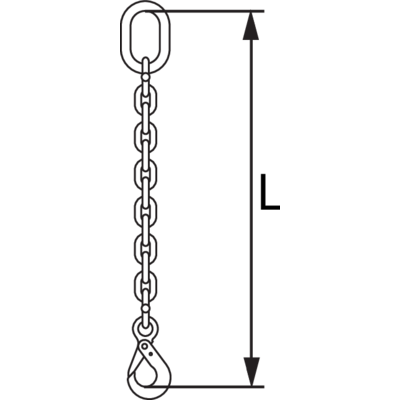

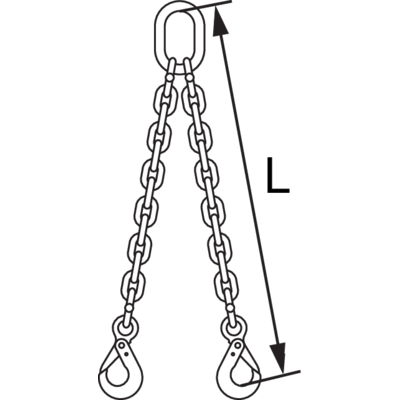

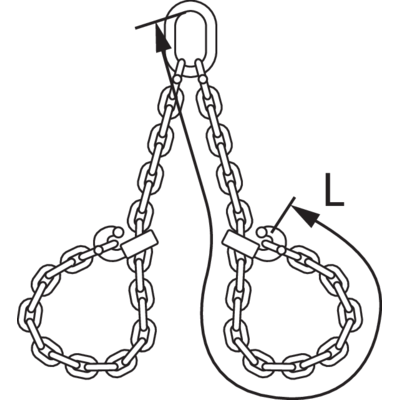

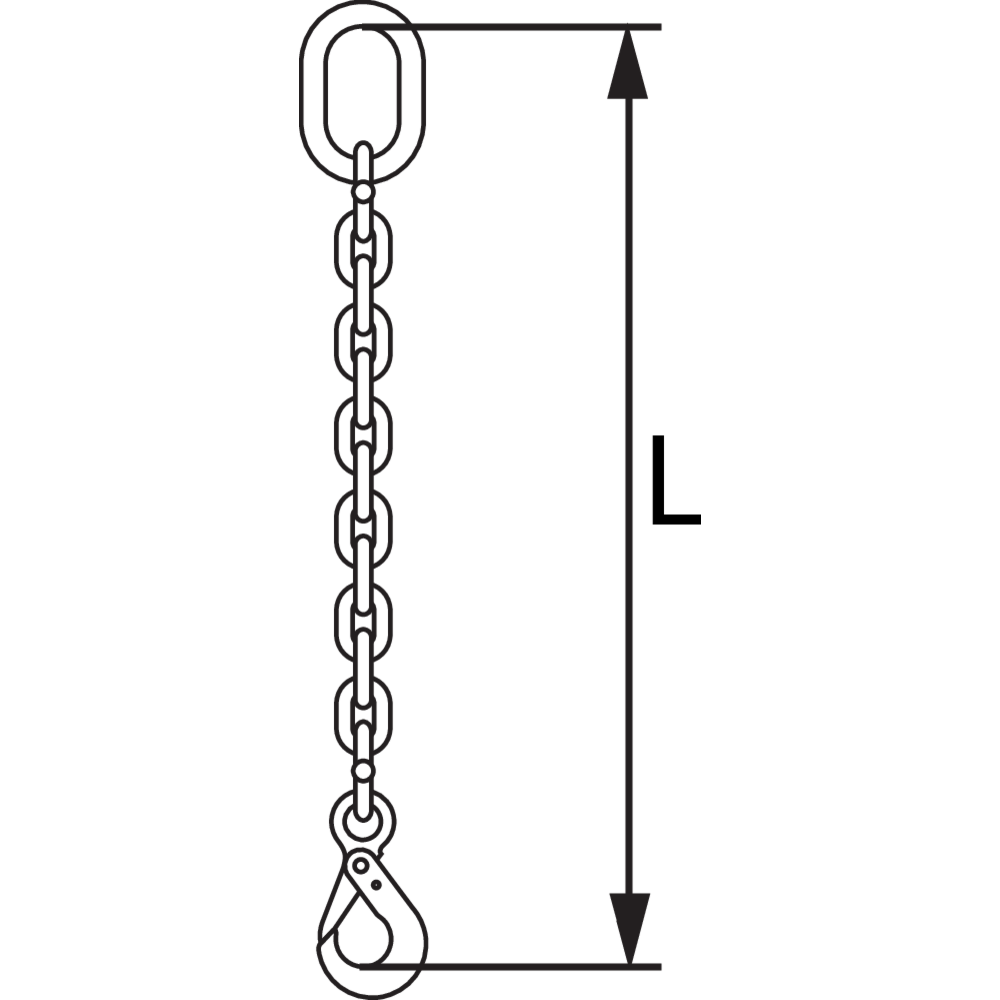

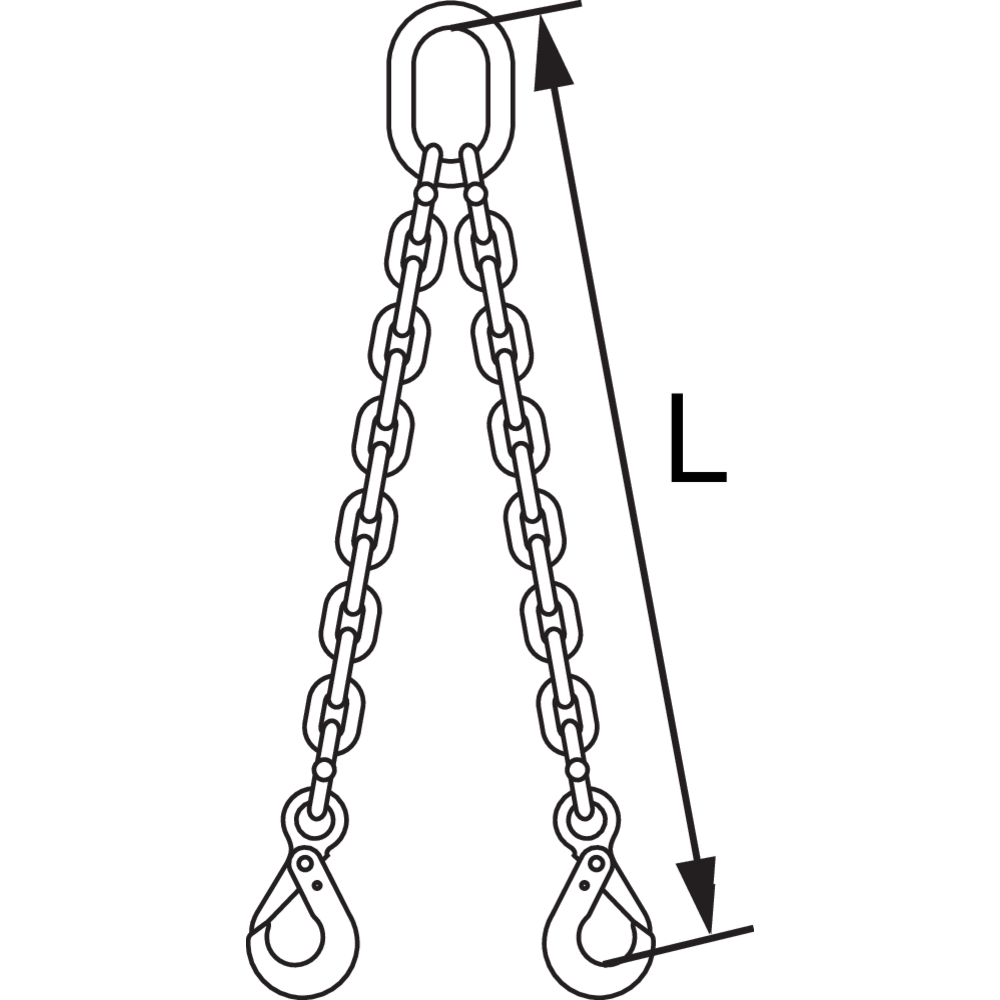

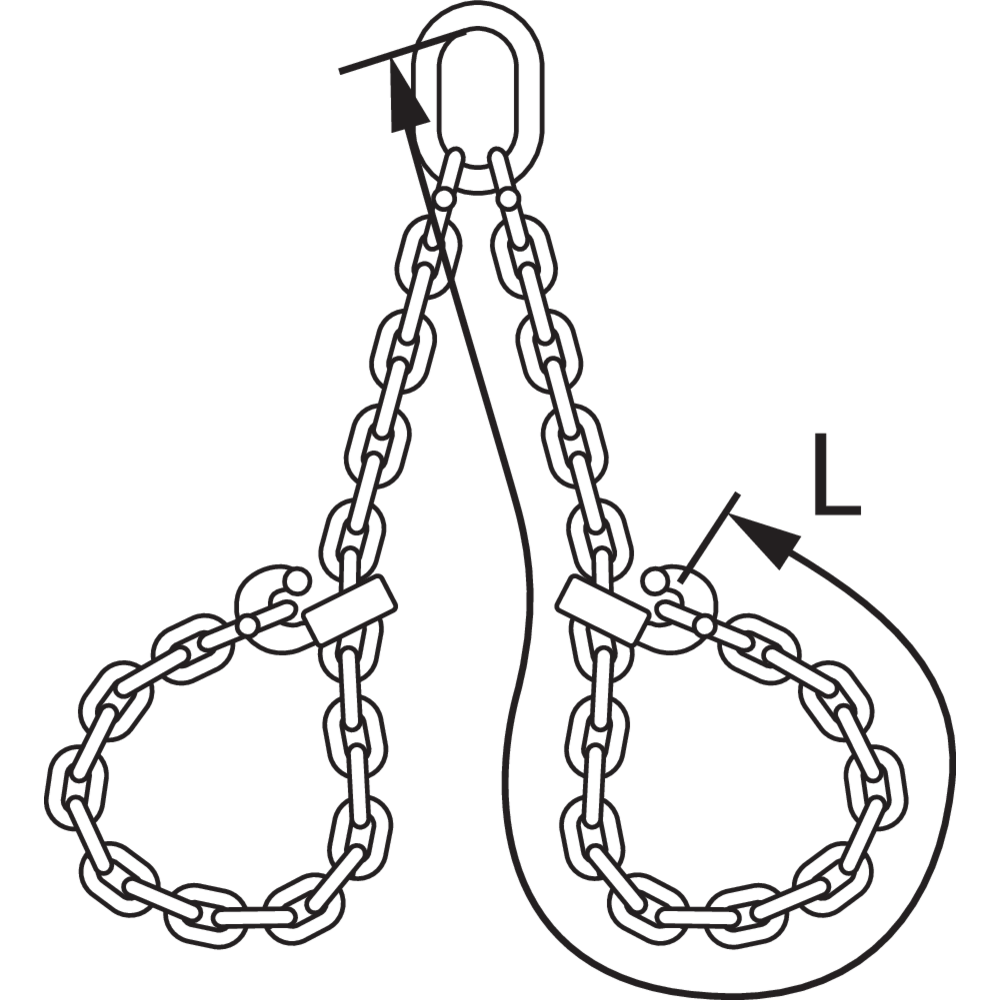

Tolerance of length

The length (L) should be measured between the "bearing points" or the circumference for endless slings.

The length on each leg should be nominal length with a tolerance of -0/+2 chain link lengths.

The difference in length (usally the same for all legs) between the shortest and longest leg in a mulit-leg sling, assembled with connecting links, should not exceed 10 mm if the sling is 2 m or less, for longer slings a value of 5 mm per metre should be used.

Chain slings - Marking

Slings are provided with a marking plate with the manufacturer's identifying mark, working load limit (WLL), length, date of manufacture and CE-marking.

![Markplate_s[new]_225mm](/sites/certex-lv/techdoc_import/Technical%20information%20general/CHAIN%20-%20LIFTING%20PRODUCTS/11641/image-thumb__11641__general-base/markning.d33a0ab6.png)

![Markplate_s[new]_225mm](/sites/certex-lv/techdoc_import/Technical%20information%20general/CHAIN%20-%20LIFTING%20PRODUCTS/11641/image-thumb__11641__general-thumb/markning.cea3d09b.png)

![Markplate_s[new]_225mm](/sites/certex-lv/techdoc_import/Technical%20information%20general/CHAIN%20-%20LIFTING%20PRODUCTS/11641/image-thumb__11641__general-base/markning.d33a0ab6.png)

Do you have any questions?

If you have any additional questions, please contact us and we will answer you.

![Markplate_s[new]_225mm](/sites/certex-lv/techdoc_import/Technical%20information%20general/CHAIN%20-%20LIFTING%20PRODUCTS/11641/image-thumb__11641__product-large/markning.c1d75ad5.png)